5 Tips for Post-Processing Your Parts

Filling Gaps

Parts may experience under extrusion in some areas, or just in general, that need to have added material. This can be done easily using some of the following products.

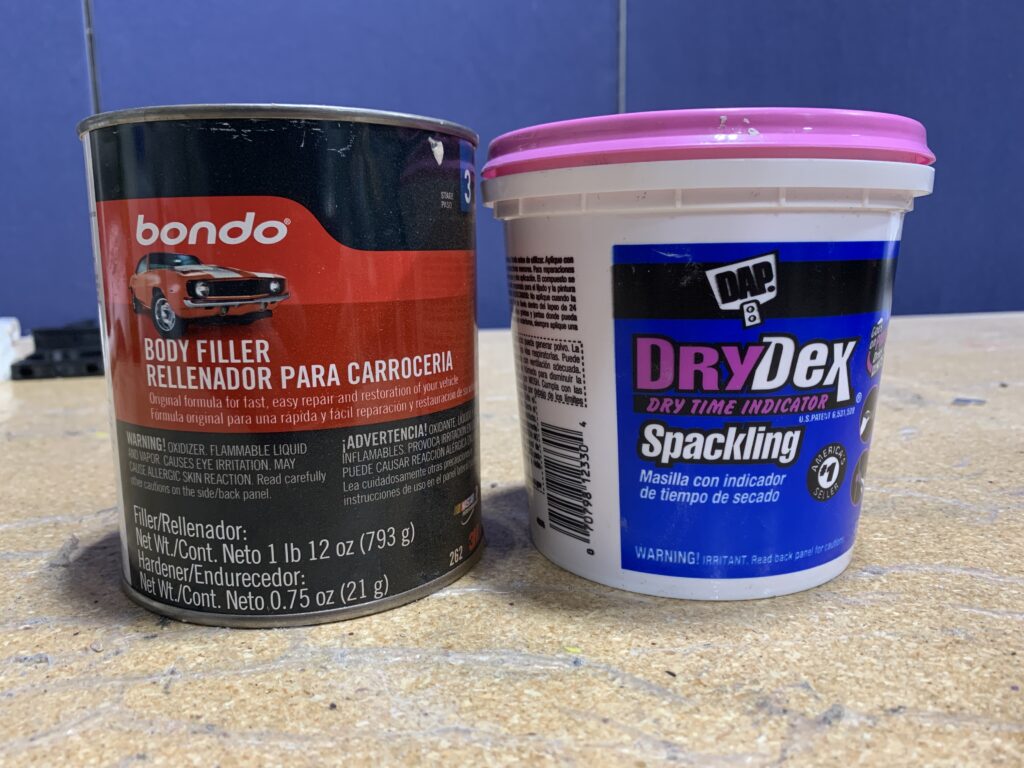

Bondo

Bondo works well for filling large gaps and dries to a very hard surface. Make sure to use proper ventilation and read the manufacturing directions before use.

Filling Primer

Primer can come in different densities and forms. Filler primer is commonly found at automotive stores. It can be used to fill small gaps and can be sanded smooth for painting. It also dries very fast.

Drywall Compound

This is the most cost efficient option and can be used to fill large or small gaps. The larger the gap, the longer it will take to dry. It shouldn’t be used on a surface that will receive force as the compound can be soft even after drying.

Sanding

Sanding Block

Whenever sanding a flat surface, or even a convex surface, it is recommended to use a sanding block or hard flat surface. This will help the surface stay flat and either parallel or perpendicular to adjacent surfaces. It will also help prevent divots that can be caused by sanding with an apparatus such as your hands.

Files

Files work great for raw prints as they can remove material rather quickly. They also come in various sizes and shapes that can help you maintain the intended form.

Grit

Sandpaper grits make a big difference and can range anywhere from 60 grit up to 2000 grit, and further. For general sanding for paint, you shouldn’t need more than 400 grit.

The lower the grit, the rougher the sandpaper. Grits in the range from 60-220 should be used on raw prints/plastic. After priming the part, grits that range from 220-400 should be used to get a smooth surface for paint. Anything above these grits is generally used for polishing purposes.

Priming

Coats

The number and the thickness of coats matters! It is recommended to do more light coats than less, heavier coats. Heavier coats will take gradually longer to properly dry. If the primer does not properly dry, it can cause issues with sanding. Make sure to use primer in a well-ventilated area and read the manufacturer’s intended directions.

Quality

Quality of primer makes a difference. There are brands such as Duplicolor™ that are automotive primers. It is good for hard surfaces. This typically dries faster than other primers as well, such as the Rustoleum ™ primer. This type of primer is recommended for surfaces that require more flex.

Painting

Cleaning

It is very important to make sure you properly clean your part from any dust or debris before painting. Using products such as cheese cloth or mineral spirits helps in this process.

Coats

Much like primer, it is recommended to use lighter coats. This will help the paint dry faster and bond better to the surface. Make sure to paint in a well-ventilated area.

Quality/Brand

The quality of spray paints makes a huge difference when painting your part. You get what you pay for typically in this instance. Paint also comes in a variety of styles such as glossy, satin, or matte. Duplicolor™ typically is a good paint for hard surfaces as it is an automotive paint. A downside to this brand is color selection. Rustoleum™ paints typically take longer to dry, but are usually more effective on a surface that requires more flexibility.

Polishing

Clear Coat

After painting, it is recommended to apply a clear coat over the paint. This will help protect the paint from impacts. Like paint, this also comes in a variety of styles such as glossy, satin, or matte. Apply in a well-ventilated area and check the manufacturer’s directions that should be located on the can.

Shine!

After the clear coat has properly cured for the manufacturer’s recommended time, you can polish the clear coat to the desired finish. If you are looking for a high shine finish, it is recommended to use a glossy clear coat. Wet sand this clear coat using a sandpaper grit of 600 or more. Eventually move from sand paper to a polish compound such as Novus ™ product and use their hierarchy of polishes.

As always, The 3D Printing Store team is available to provide demonstrations, professional development courses, and educational courses to you and your team. Contact us or email arausch@the3dprintingstore.com for inquiries.