Additive manufacturing the highest quality parts for your project

Feel confident knowing that you will receive only the highest quality parts that not only meet all of your project’s requirements but exceed expectations.

100+

Materials available

25k+

Parts printed

50+

Years combined experience

100k+

Hours of 3D printing

Our 3D Printing Technologies

The 3D Printing Store uses the latest technologies in additive manufacturing to guarantee the best results for your project.

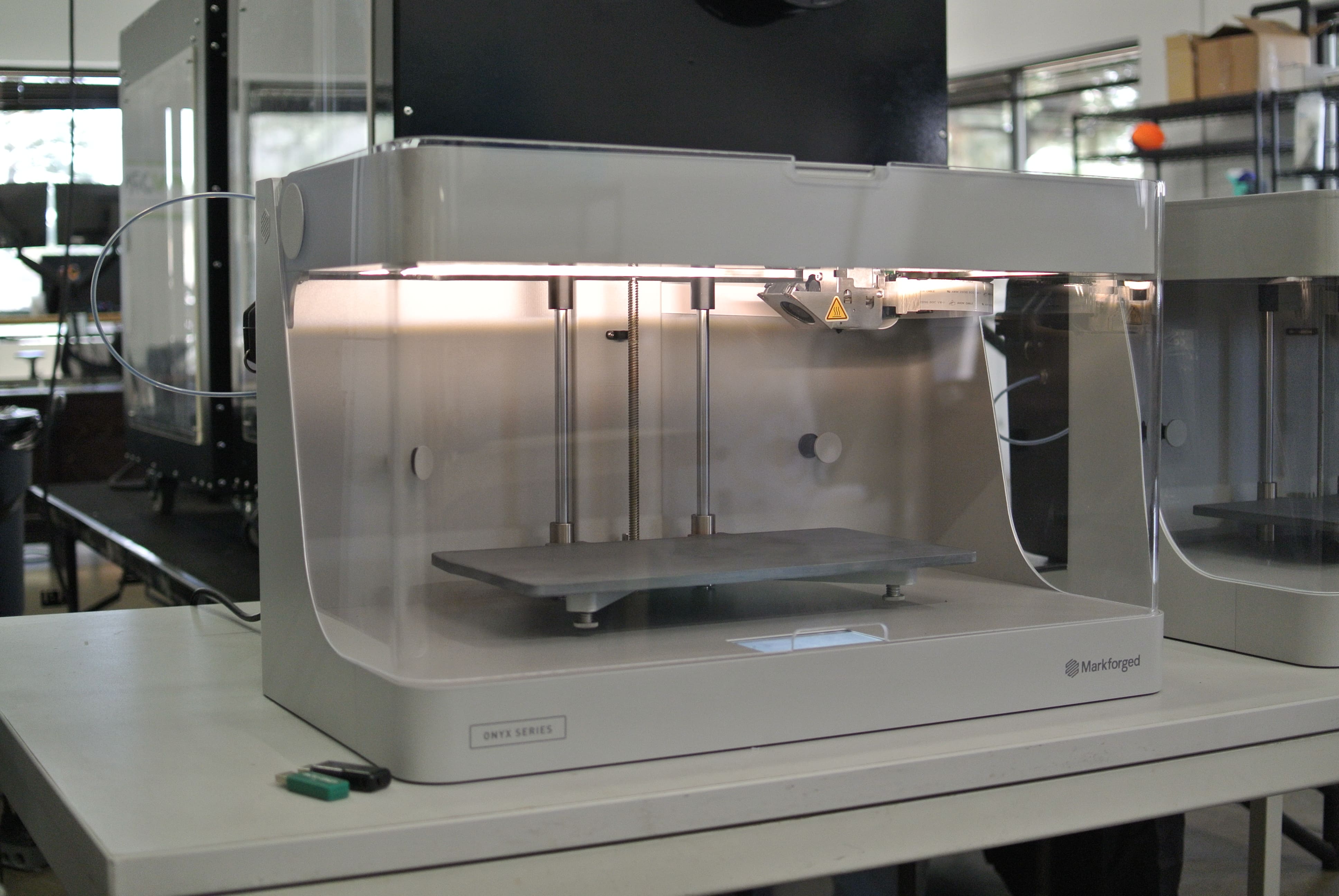

Fused Deposition Modeling (FDM)

With low costs and a wide array of thermoplastic materials, FDM printers are great for prototyping and producing concept models.

- Low material costs

- Wide array of materials

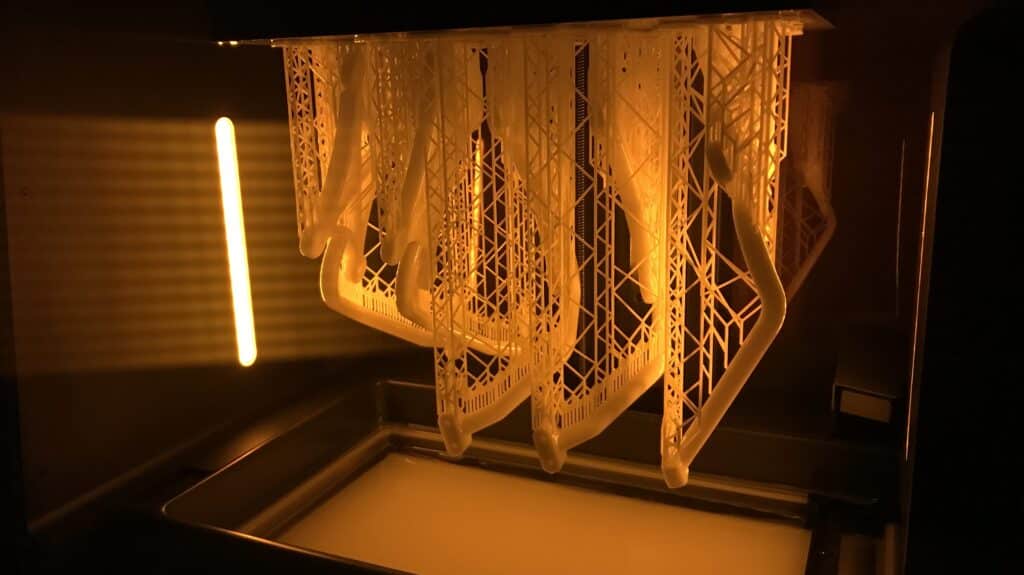

Stereolithography (SLA)

A fine resolution and tight tolerances allow for solid or hollow parts with very smooth surface finish and fine details.

- Fine details

- Smooth finishes

Digital Light Processing (DLP)

DLP printers cure the entire profile at once making for faster build times with high surface finish and details.

- Faster builds

- High level of detail

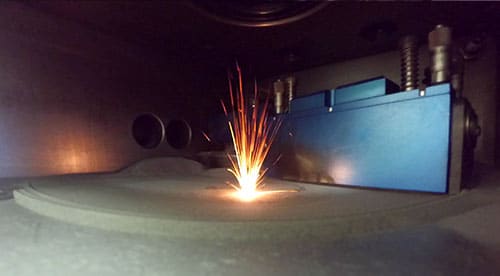

Selective Laser Sintering (SLS)

SLS printers allow for high surface finish and detail while not requiring the support structure of many other technologies.

- Durable and versatile

- Perfect for prototyping and end products

Large Format & High Resolution Printing

Our largest high-resolution DLP resin printer has one of the largest build volumes on the market at 30”x30”x48”. We have several options for full-color printing using either powder-based printing or full-color FDM.

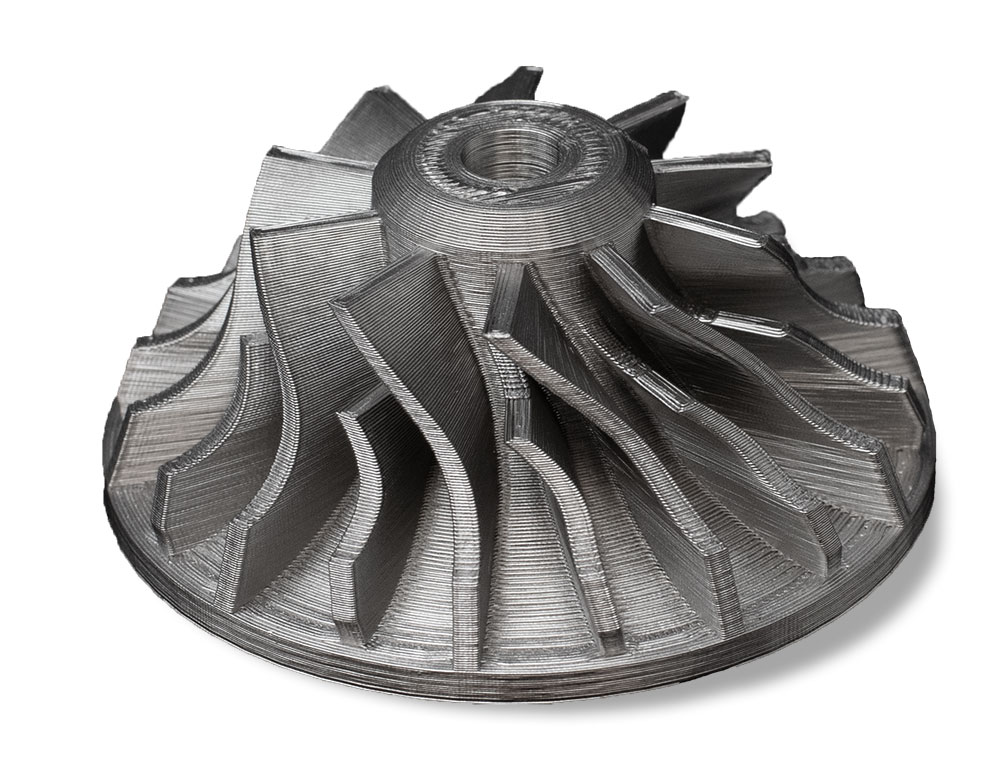

Multi-Material & Engineering Material Printing

We can print multiple materials within a single printed object for new applications and reduced assembly counts. Get high-performance chemical and heat-resistant engineering materials.

Low/Medium Volume Production

Large format DLP printers can print a full build volume in less than 24 hours allowing for low to medium run production.

We’re always growing our catalog of materials and print technologies

With our ever-growing catalog of materials and print technologies, we are constantly evolving to meet the specific needs of our customers at our 3D printing store.