Tighten the screws on your printer

The screws that hold together the printer can come loose over time and through shipping. It’s good to go through the printer and tighten these every few months.

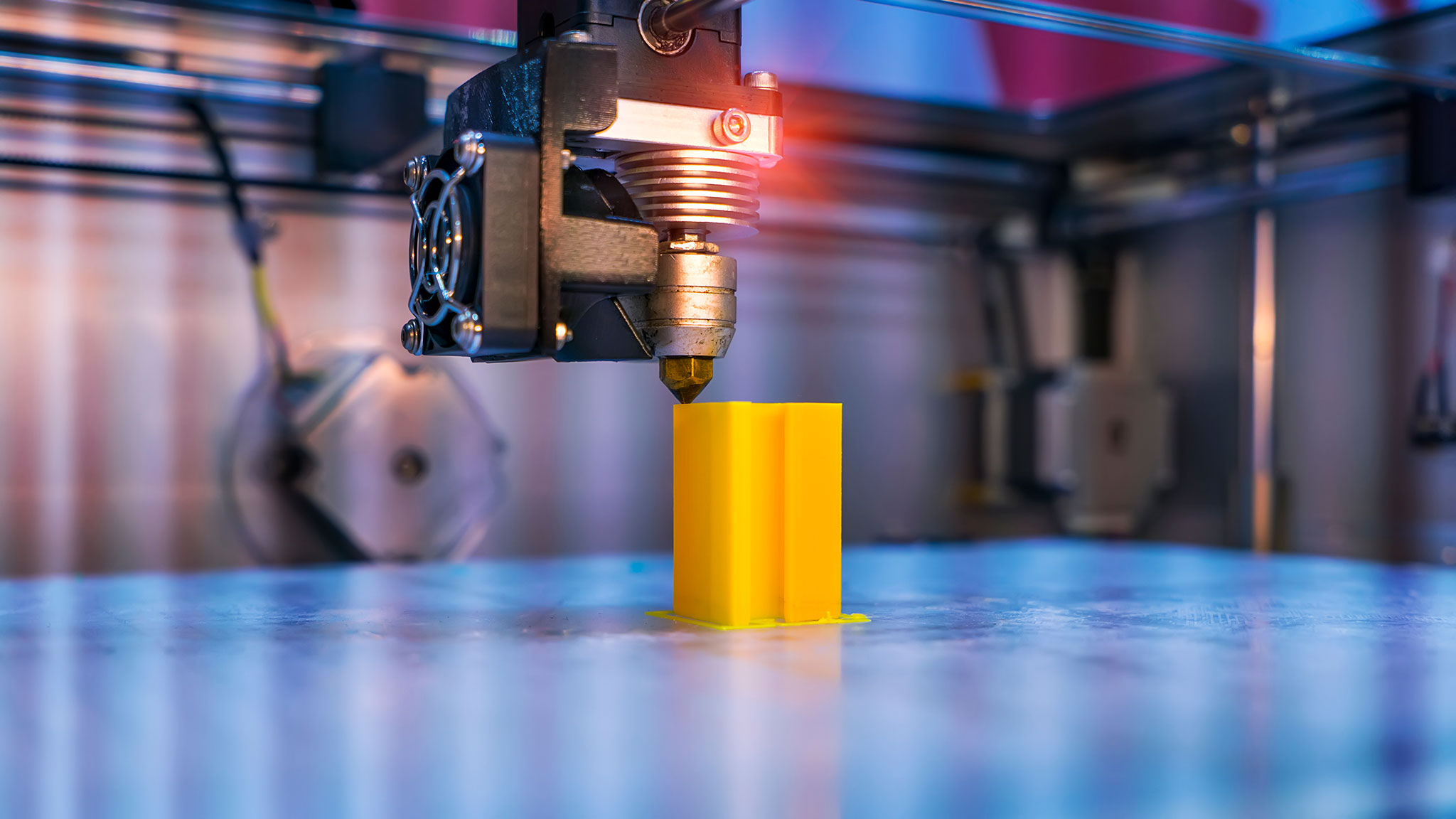

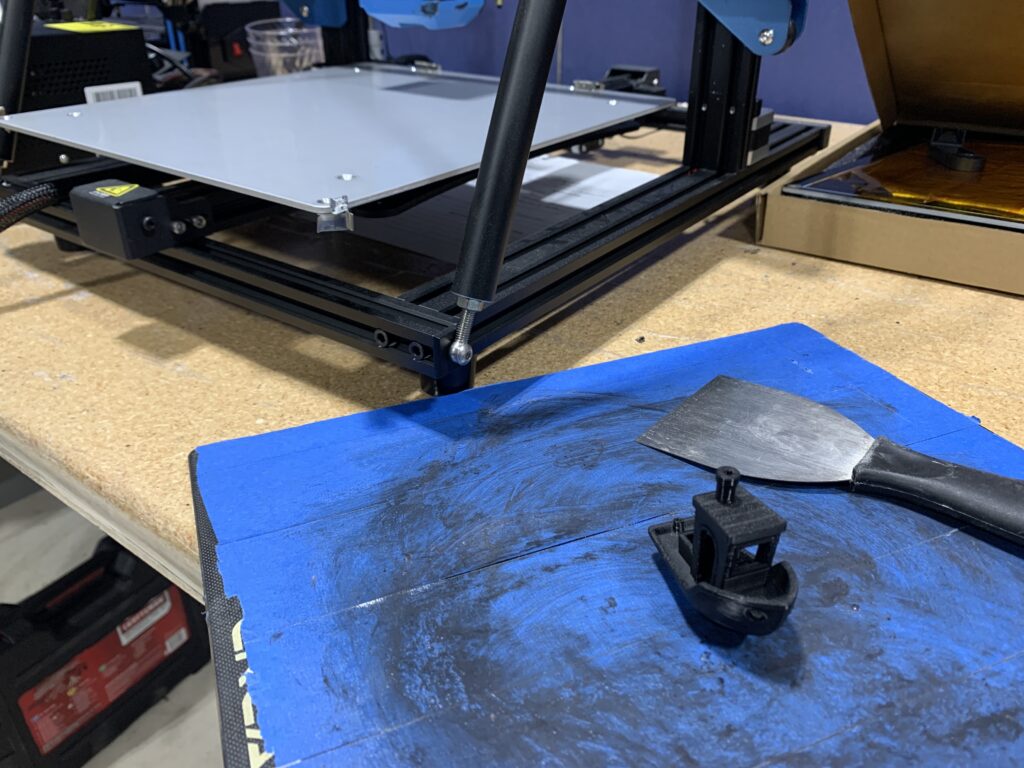

Level your printer bed

Beds can become unlevel after a certain amount of time. Glass beds are a popular choice and allow you to remove the bed to access the print. Signs that your bed is not level is the print not sticking to the bed, nozzle running into bed.

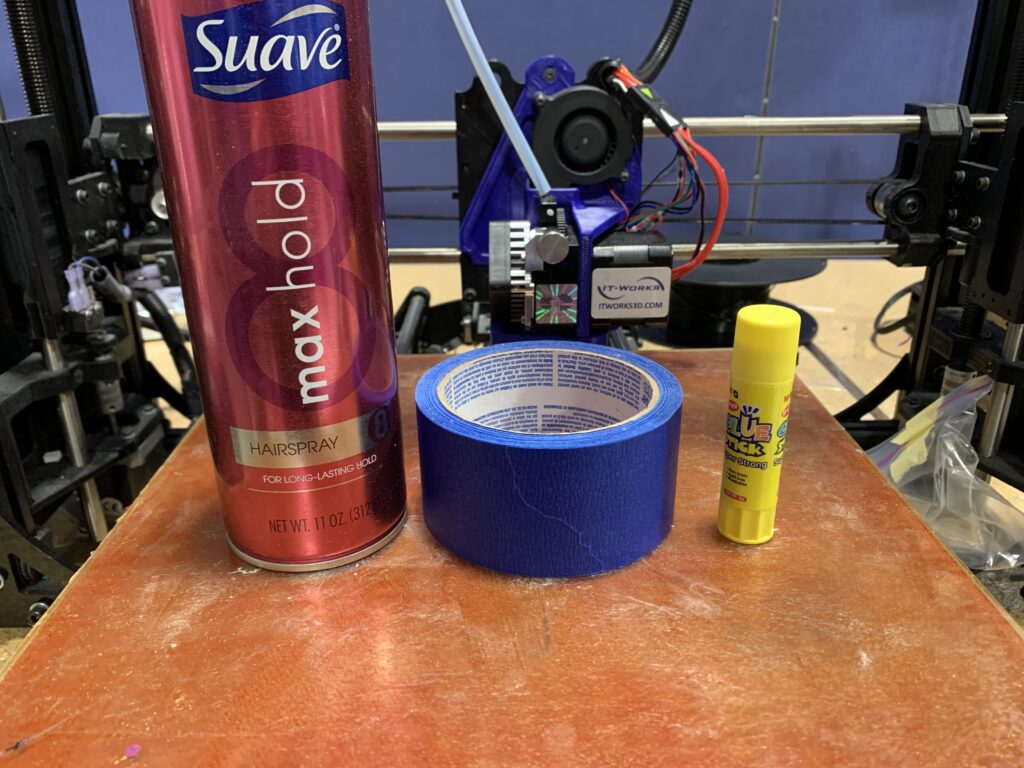

Different kinds of adhesive can be applied to beds to help with adhering. Some of these include: blue tape, hair spray, and a glue stick, amongst others. Check with the filament manufacturer to see what is best for the material.

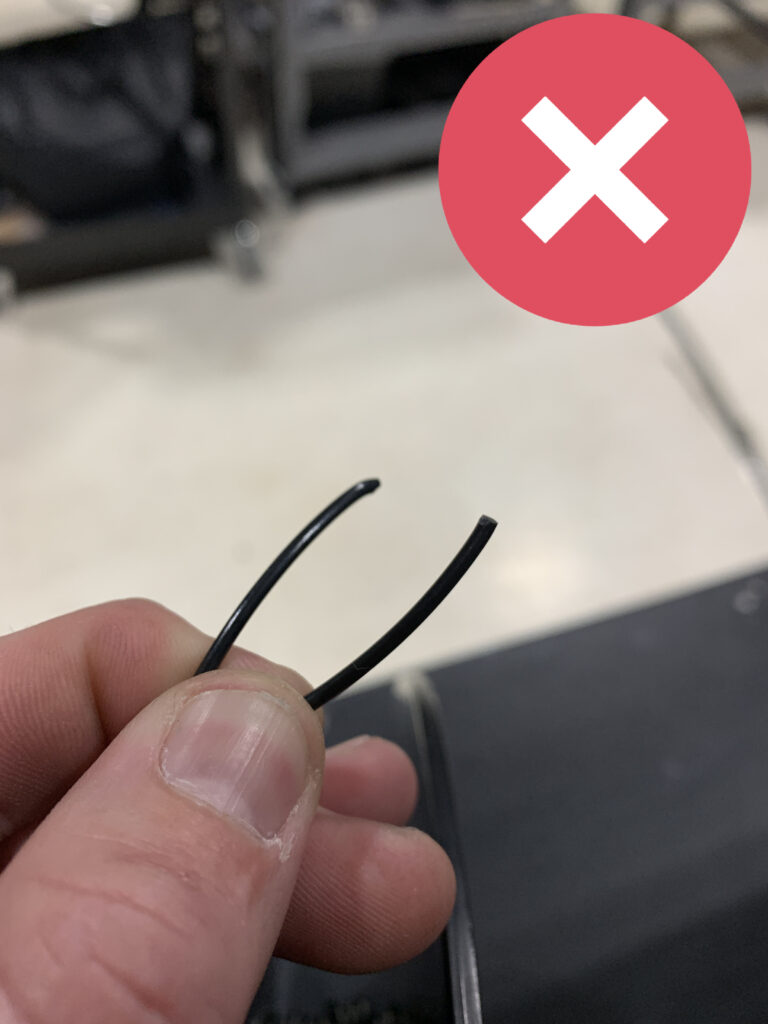

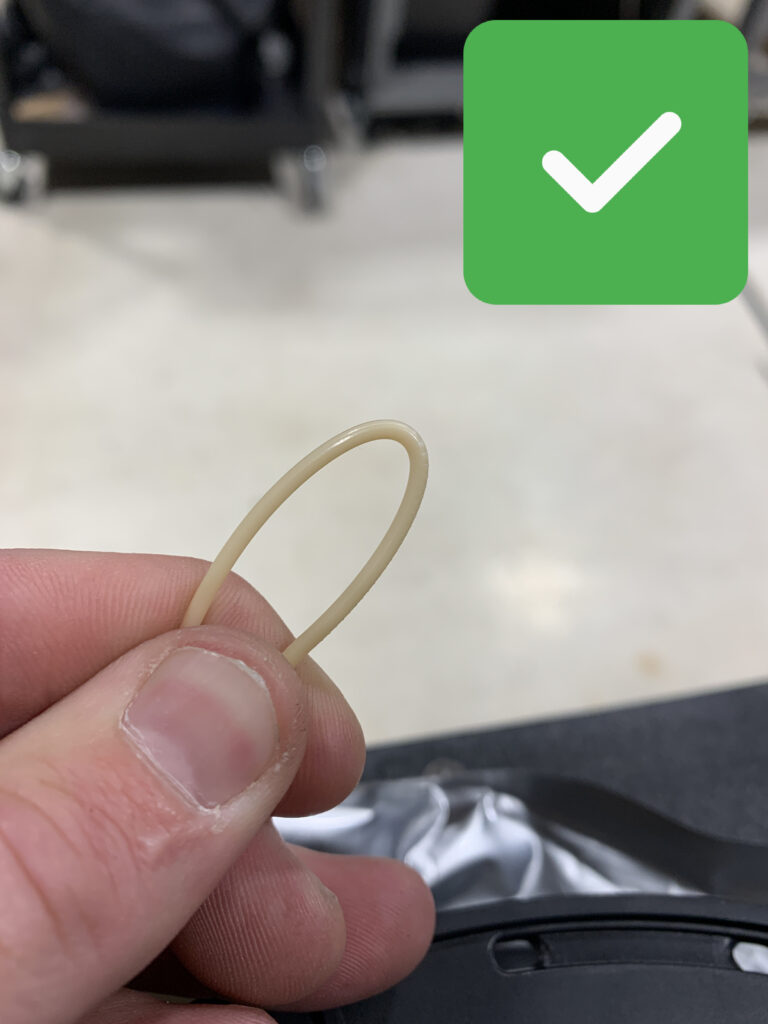

Store your filament properly

Filament can expire over time. It’s best to store filament in a cool, dry location to ensure longevity of the material. Signs of bad filament are under extrusion, popping noise while it prints, and it doesn’t like to stick to the bed. Also, if the nozzle keeps clogging and breaks easily.

Clean your printer nozzle

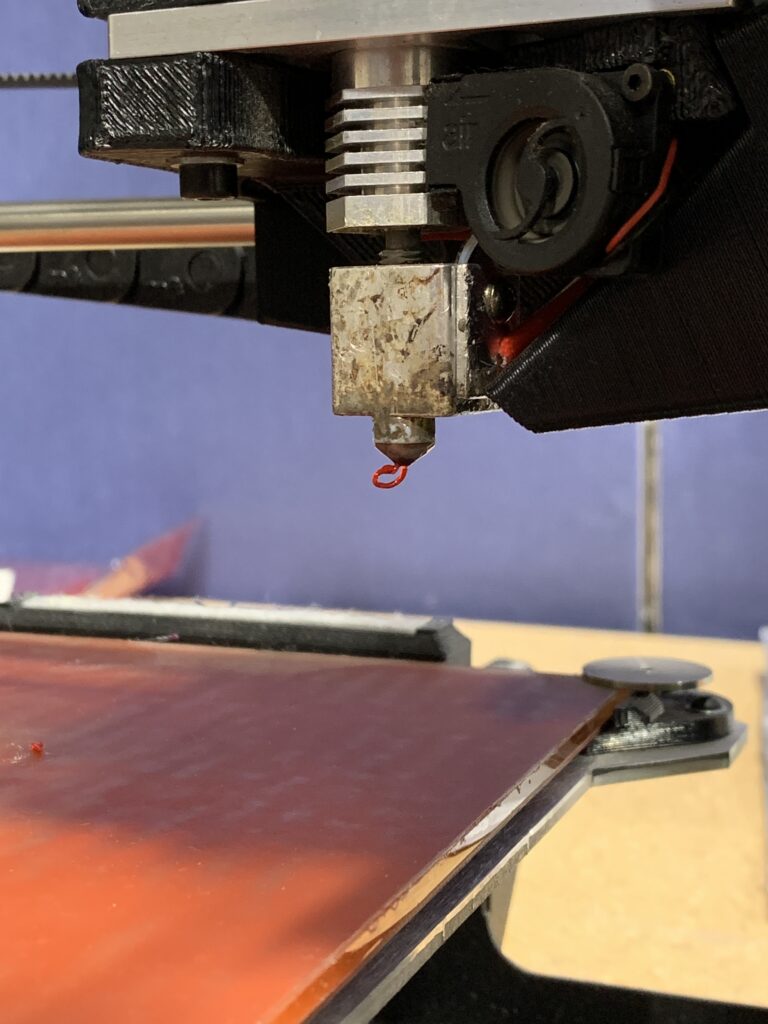

Nozzles can clog after extended use. Signs of a clogged nozzle are that plastic is not coming out of the nozzle, prints are not sticking to the bed, filament curling when it exits the nozzle, and under extrusion.

Not every nozzle is compatible with every printer. Check with the manufacturer information to determine what type of nozzle you need.

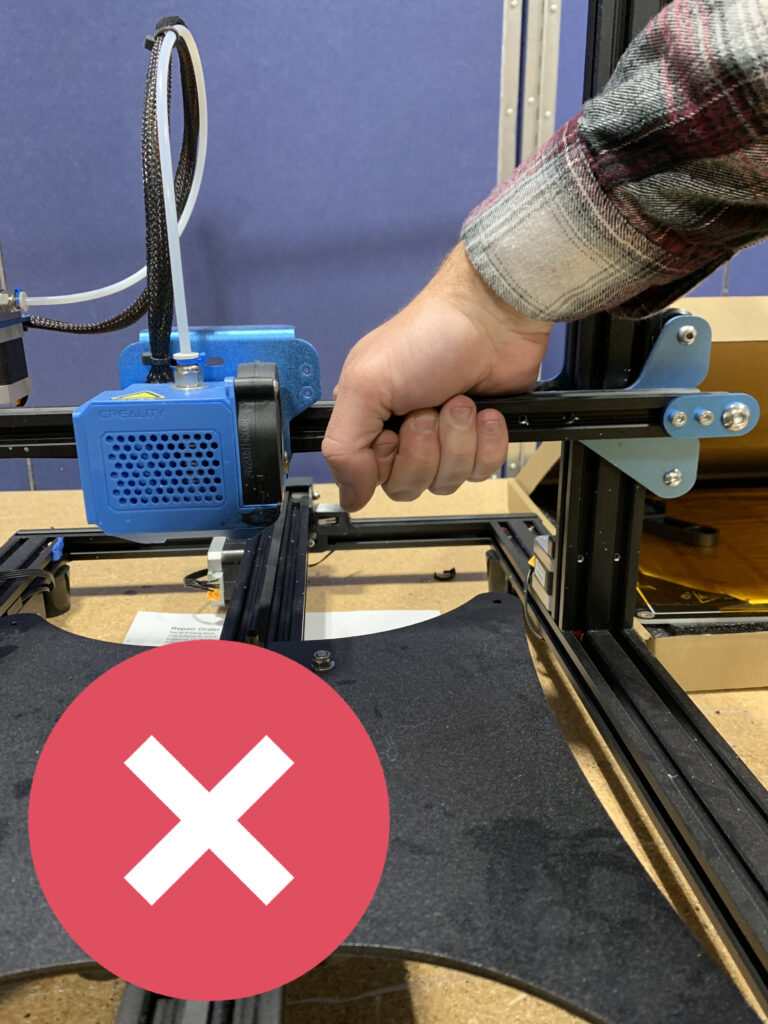

Don’t move the printer axis by hand

Moving the axes by hand is not recommended and can ruin the main board of the printer. If possible use the commands within the menus of your printer to move the axes.

If you need to move an axis by hand, power the printer off and remove the power cord and move the axis/ assembly slowly to desired location .

As always, The 3D Printing Store team is available to provide demonstrations, professional development courses, and educational courses to you and your team. Contact us or email arausch@the3dprintingstore.com for inquiries.