Stereolithography

Benefits

- Very fine resolution

- Parts can be solid or hollow

- Tight tolerances

Disadvantages

- Slow build times

- Can be expensive for complex models

How it works

Stereolithography (SLA) was the first additive manufacturing technology, being invented in the 1980s. SLA printing uses a laser to trace out slices of a 3D liquid photopolymer resin curing the light activated resin in specific areas first to a build plate then to subsequent layers. Once a build is complete, the excess resin is washed off using a light solvent and then is post-cured with heat or UV light, or both.

Additional Considerations

- Because SLA only uses one material, support removal often leaves behind small dimples and pimples.

- Because the point of the laser is very fine, SLA printers produce parts with a very smooth surface finish with fine details.

- The photopolymer resins vary between manufacturers with a range between prototyping, engineering, and TPU materials.

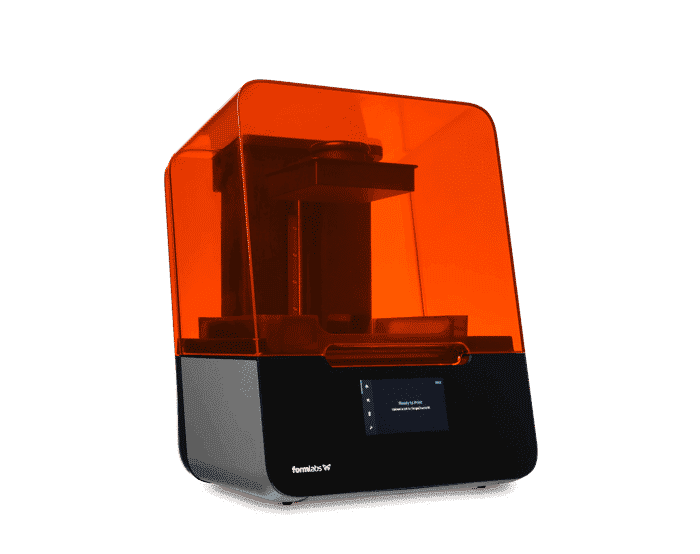

3DPS SLA Prints Exclusively with Formlabs

The 3D Printing Store uses the latest technologies by Formlabs to meet tight tolerances and dimensional accuracy required by customers. 3DPS has a variety of Formlabs resins in-stock and ready to print! Typical turnaround for a print is 1 – 2 business days.

Formlabs Form 3BL

Build Volume: 13.2″ x 7.9″ x 11″

- Great for Large Prints

- Can fit Multiple Parts on Plate for Long and Reliable Builds

- Bio-Compatible Materials

Formlabs UV Resin Technical Data Sheets:

Formlabs General Resins TDS:

Draft | View Technical Data

White, Black, Clear and Grey | View Technical Data

Formlabs Engineering Resins TDS:

Rigid 10k | View Technical Data

Rigid 4k | View Technical Data

High Temp | View Technical Data

Tough 2000 | View Technical Data

Durable | View Technical Data

Elastic 50A | View Technical Data

Flexible 80A | View Technical Data