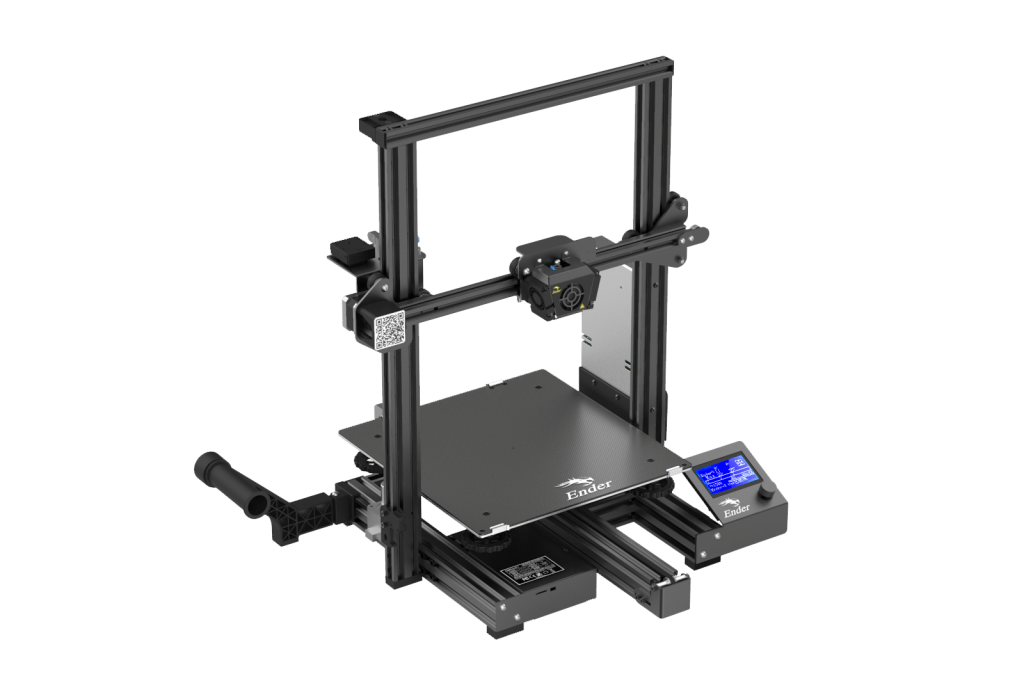

Tempered Glass

One of the best and easiest upgrades you can perform to an Ender 3 printer is a tempered glass bed. Creality offers a bed that is perforated and composed of carbon silica. This bed offers a few advantages over the flexible bed that typically comes stock with an Ender 3.

Prints stick better to this bed. Unlike the flexible bed, the glass build plate is already perforated which improves first layer adhesion as there are small holes for the filament to get into. The glass also has the availability of adding other compounds to improve adhesion such as a glue stick, hairspray, etc. Applying these products to the flexible bed would work. However, removing the adhesive products from the flexible build plate can be troublesome.

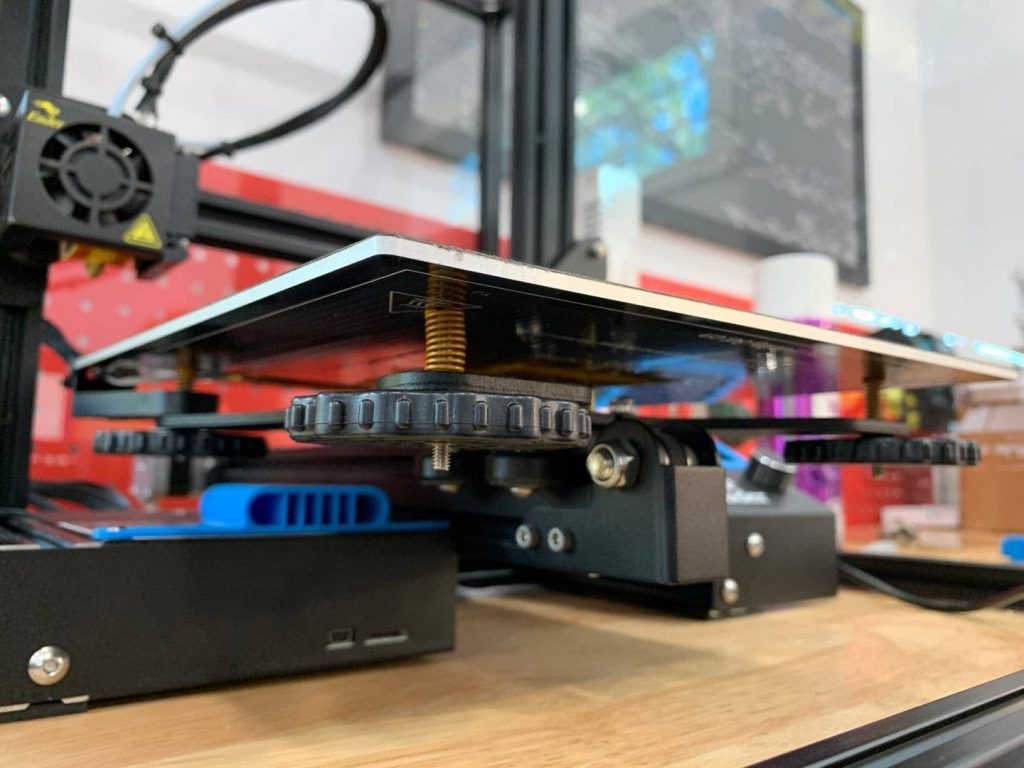

Bed Leveling Wheels and Springs

Out of the box, Ender 3s (like most other printers) will have 4 springs and 4 knobs underneath the print bed. These are used for leveling the bed. These knobs are notoriously small and can make it difficult to level the bed. In addition, the springs lose compression over time.

An upgrade can replace the stock bedknobs with larger diameter wheels and thicker springs. This upgrade helps a few things. Firstly, it helps with the general level process– not as much of the wheel needs to be turned to make small adjustments. This means that the speed of which you level the bed as well as accuracy is increased. These knobs are also much easier to locate and control when turning– which again helps with time and accuracy of leveling the bed.

Nozzle

Ender 3s, as well as numerous other printers, typically come installed with a .4mm brass nozzle. These nozzles work great– especially if you are using PLA exclusively as your filament. However, over time, these nozzles can start to break down due to heat and friction.

There are many third party companies such as Microswiss that produce nozzles that are made from harder materials like hardened steel and even ruby! These nozzles excel in a couple things. They generally last longer since they are made of a harder material. They are also optimal for printing higher end materials such as carbon fiber. Generally, brass nozzles are not suited for high abrasive filaments.

Nozzles also come in a variety of sizes ranging from .2mm up to 1.5mm.

With a larger nozzle diameter, you can print faster. However, quality is then sacrificed.

Layer height is typically defined by nozzle size. The general rule of thumb is that the layer height should not be much more than half of the nozzle diameter. So, if you are using a .4mm nozzle, then it is generally ideal to use a .2mm layer height.

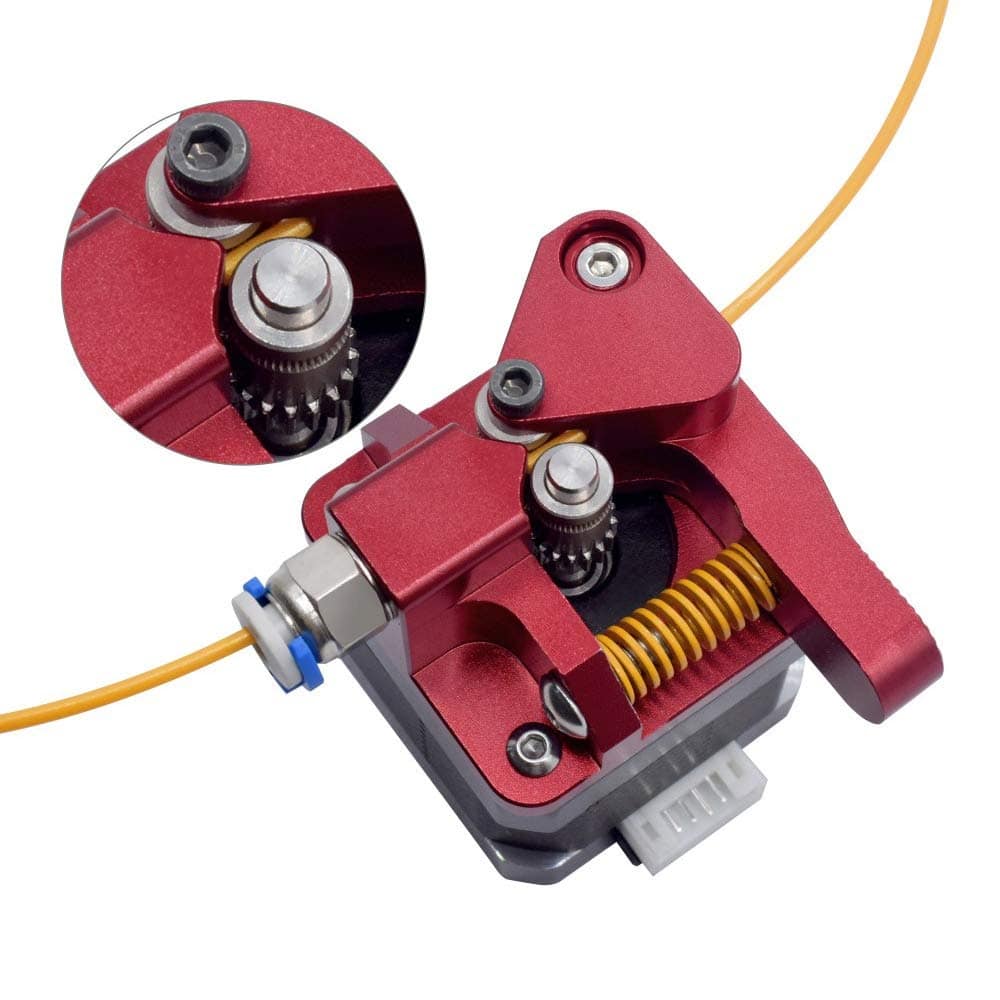

Extruder

Ender 3s as well as other Creality printers typically come with an extruder that is loathed on the left side of your printer. This part is made with plastic, and after time the plastic can become brittle and break. This will cause the drive gear within the extruder to lose grip on the filament. Then, the filament will no longer extrude properly or at all.

There are third party companies that make an upgraded extruder that is compatible with stock Creality machines. This upgrade offers a few improvements over its predecessor. The body is made from metal components; so, the chances of it breaking are much less. New systems also offer a dual feed system. This basically means that there are two drive gears pushing the filament rather than the conventional one. This helps keep a constant flow rate of filament from the nozzle. The spring is also upgraded so that it keeps proper tension on your filament over time without adjusting it.

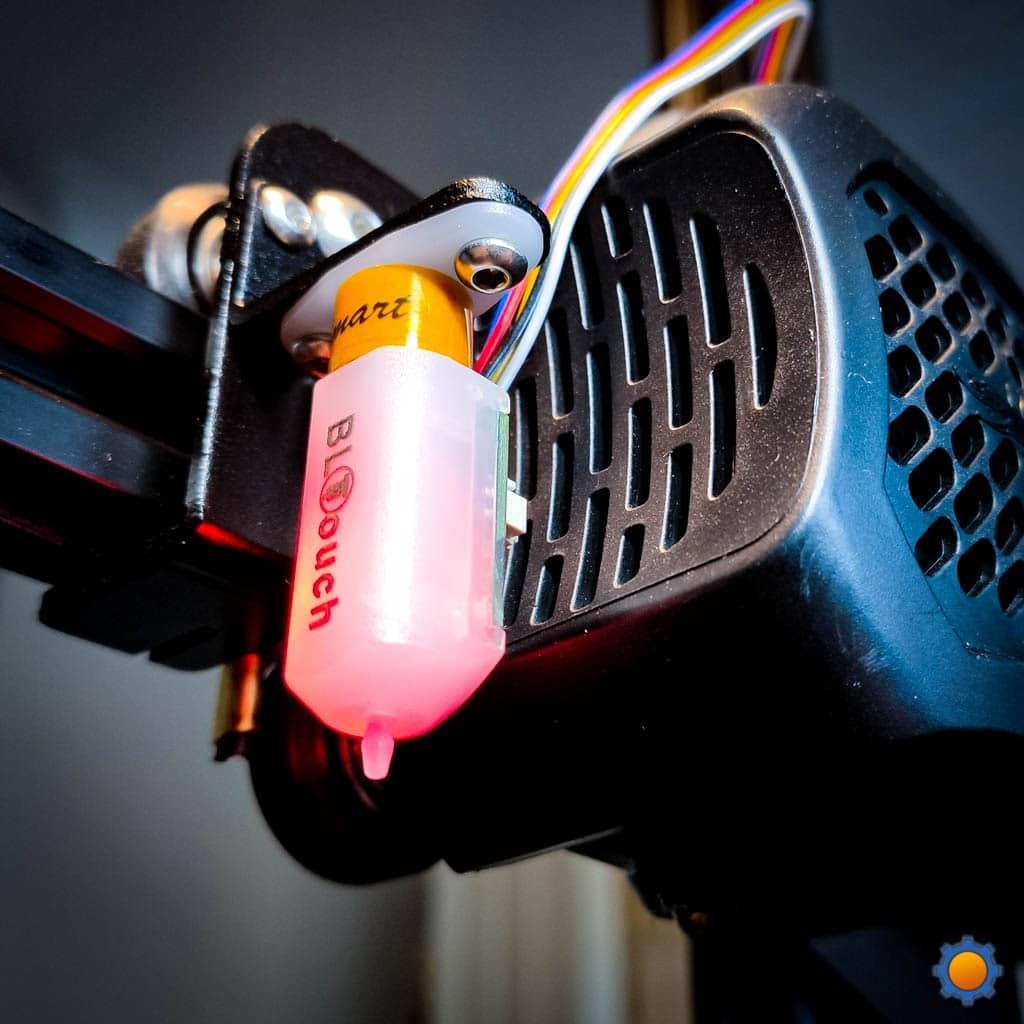

BL Touch

The current method for leveling a bed is to use a sheet of paper and place it under your nozzle and while turning the knobs until there is very little friction. However, this method has its own flaws. Beds can become unlevel very easily if you are not careful. Additionally, if you apply a lot of force to the bed when removing a part, this can unlevel it as well. Manually leveling your printer is now a thing of the past.

Creality has teamed up with ANTCLABS to develop the BL Touch which is an auto leveling system for your printer. This system is easy to install and can save you a lot of time on future leveling. This system uses a probe to tell the printer the bed height at multiple locations. The printer is then able to adapt to those heights to raise and lower itself accordingly. The system is not totally foolproof. However, it holds promise if you are having to level your bed before every print.

As always, The 3D Printing Store team is available to provide demonstrations, professional development courses, and educational courses to you and your team. Contact us or email arausch@the3dprintingstore.com for inquiries.