3D printing is able to accomplish incredible designs that would be extremely difficult or impossible to machine. There are many benefits to this including: increased strength, weight reduction, assembly costs reduction, waste reduction, and more. Naturally, people want to see these benefits realized with materials other than plastic. Metal, ceramics, and more have all been added to the catalog of materials suitable for 3D printing due to increased interest and research. However, most metal additive manufacturing technologies require very different and expensive technology when compared to many of the plastic additive manufacturing technologies. Metal additive manufacturing (AM) primarily uses high powered lasers or electron beams to create parts. While this technology is impressive, it can also lead to many problems. This has led other printer and material manufacturers to investigate technologies that could be used to achieve metal parts at much lower production costs. Recently, there have been several companies to succeed in doing so. This article looks at the current drawbacks as well as new technologies that are helping democratize metal AM and may even allow users to print metal parts on their own home desktop printers.

Powder Bed Fusion Metal AM

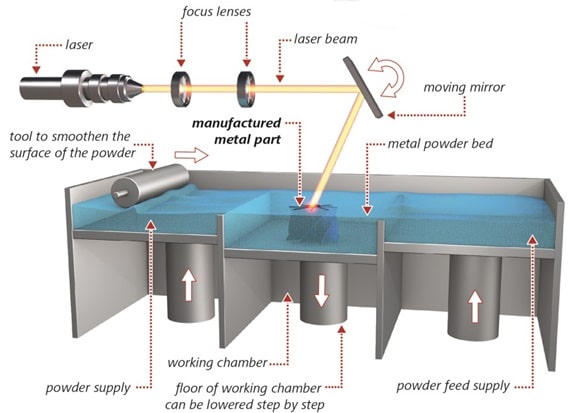

To better understand the deterrents associated with many of the metal AM technologies, it is first useful to understand how they work. Most of the metal AM printers available on the market are powder bed fusion technology printers. Powder bed fusion (PBF) printing describes several similar additive manufacturing processes which all use some high energy source to carefully melt fine metal powder together layer by layer. This is accomplished by raking a precise thickness of material across the print surface and allowing the energy source (typically a laser or an electron beam) to draw out the layer. Once the layer is complete, the build plate moves, another layer of material is raked across the top, and the process is repeated. Once the print is complete, the excess powder is carefully removed– usually with compressed air and can be recycled with new material at a specific ratio specified by the tool manufacturer. From there, the part can be sintered for further strengthening. The whole process is very fascinating and it results in strong, beautiful parts. However, the process also has some aspects that make it undesirable.

Metal powder is dangerous to work with as inhaling it is damaging to the lungs. It is also a skin and eye irritant. This means that anytime it is being handled, it must be done so with care to ensure the operator’s safety. Also, due to the packed bed technology, excess powder must be removed. While this material can be recycled, it must be mixed in with fresh material at a certain rate which leads to additional waste and expenses. The sophistication of the technology also comes with a price tag. High power energy sources are expensive pieces of equipment, and if they break and require replacement or repair, it is very costly. Also, they are expensive to run. Selective laser melting (SLM) machines are hundreds of thousands of dollars– making them accessible only to large companies that can afford the high upfront price tag. Additionally, setup and removal are difficult as changing between materials is cumbersome and part removal from the print bed usually requires machining to remove. Even operating the machines requires extensive knowledge of the specific metal material properties that are being printed in order to get the right amount of power to effectively melt the powder together.

PBF metal AM certainly is impressive and definitely has its use cases in industries such as aerospace, manufacturing tooling, automotive, and more. However, it is hard to justify the price and complexity for many jobs for people just looking to create functional prototypes, art pieces, or many other applications. On the other hand, fused deposition modelling (FDM) printing is cheap, easy to operate, and safe to use. Several companies have realized this and successfully developed materials and processes to print metal parts much more easily.

FDM Metal AM

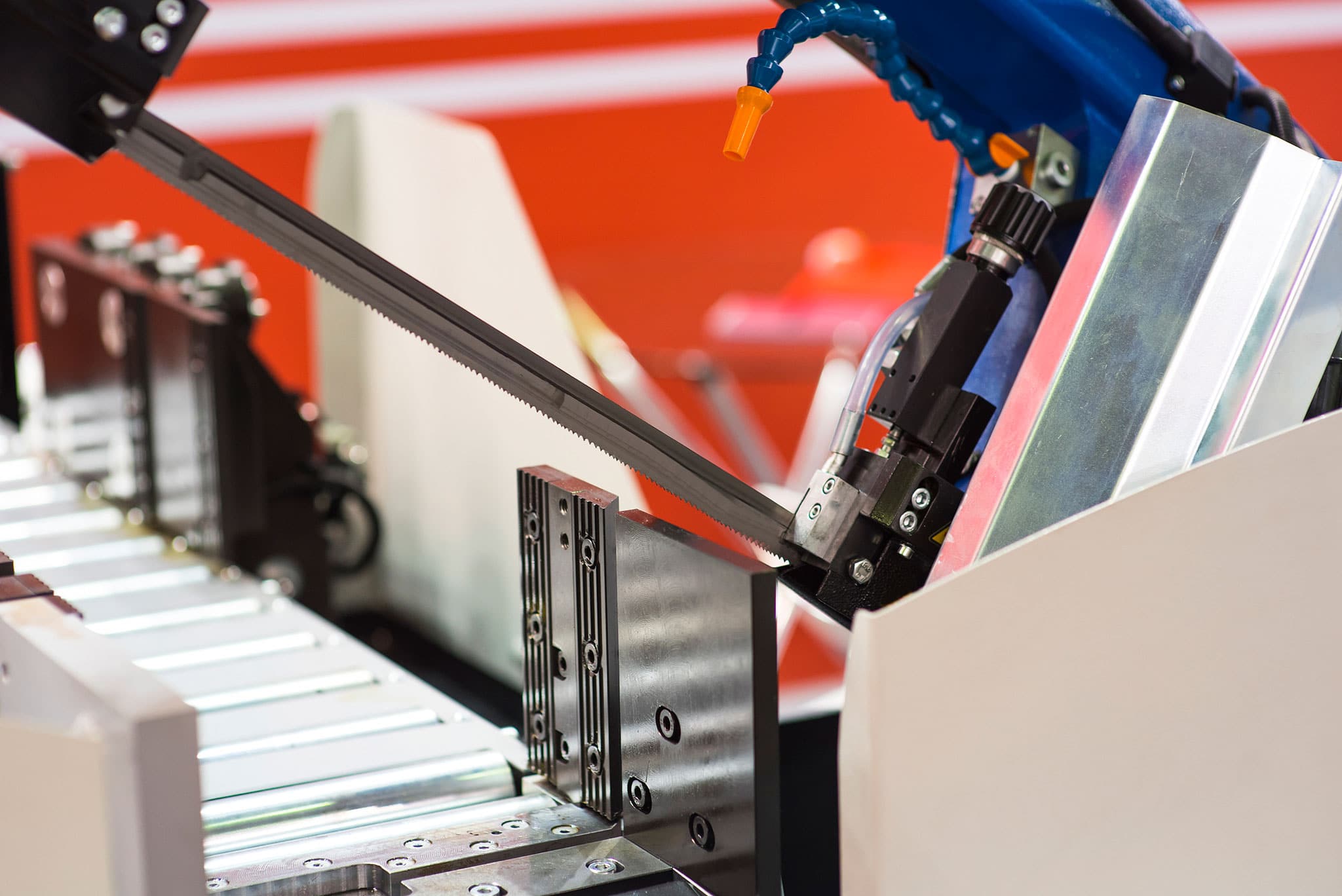

FDM printing is something that most people are familiar with by now. It is a fairly simple process. Filament of a specified diameter is pulled through a hot nozzle at around 200-300° C for most materials while the nozzle is moved in 3 axes to deposit material creating a part. But with such low nozzle temperatures, how can you print metal? Most metals melt at well above 1000° C! The clever way that this is circumvented is by creating plastic composites such as polylactic acid (PLA) with fine metal powder dispersed within the material. The weight of this being that with minimal modifications to the machine (a hardened steel or jewel tip nozzle), any desktop FDM printer can be used to print a metal part, including printers as cheap as the $200 Creality Ender 3. One company who The 3D Printing Store has worked with, and has seen great success in their materials catalog, is Virtual Foundry.

Using their bronze filament material, we have printed several parts on an 8 year old Makerbot Replicator 2 and seen similar success with many of our other printers using different materials.The price of printing parts is a factor of 10x cheaper than PBF printed metal parts. Since the powders are dispersed in plastic, safety is also no longer an issue. While support material is required, there is significantly less waste than PBF metal printing. Additionally, switching between metals is as easy as switching between any other material on an FDM printer. The parts can also be sanded after printing to achieve a higher quality surface finish. Once the parts are completed printing, they can also be sintered in order to remove the excess plastic deposited as well as strengthen the bonds between the metal particles. This results in a strong metal part that can be used for functional applications.

Some of the materials that are available are:

- Aluminum 6061

- Bronze

- Copper

- High Carbon Iron

- Inconel

- Stainless Steel

- Tungsten

- Titanium

… and more.

There are also other options that have a closed ecosystem such as the Markforged Metal X. The Metal X is a full metal system including the materials profiles, printer, sintering oven, and wash. It is more expensive than an at home FDM printer, but still less expensive to produce parts than using PBF printing.

It is important to note that FDM metal parts are not the same strength as machined parts, or even PBF printed parts, even after sintering. Due to the porosity inherent to the FDM printing method, the metal particles are not as strongly bonded. However, for applications without stringent mechanical and strength requirements, it is a great technique for achieving high quality complicated metal parts. Also, other interesting material properties are still captured when using this material as well. Examples are radiation shielding from Tungsten, conductivity from copper, or even oxidation of bronze. FDM metal printing accomplishes many of the same functions as PBF printing at a fraction of the cost– allowing more people to develop, prototype, and manufacture their next idea.

Metal AM has come a long way in a short time, and I think that we will continue to see it grow even more. The ability for people to now bring metal parts to their desktop printers has the potential to change product development; it is exciting to see products, art, and ideas come to life, shaping the future of manufacturing. In the same way that AM democratized the plastics manufacturing industry, it is now expanding into metal fabrication, ceramics, and more. While it is not a direct replacement for PBF metal printing or traditional metal manufacturing such as casting, forging, etc., it is a suitable replacement for many applications at a significantly cheaper price.

If you would like to print your next part in metal and realize the benefits of real functional metal parts, contact us at project@the3dprintingstore.com. To purchase your own virtual foundry metal filament, visit their website at https://www.thevirtualfoundry.com/