Digital Manufacturing isn’t just about technology or process, it is about the ability to be flexible and to move quickly. Traditional manufacturing can produce innumerable things and incredible amounts of them, but traditional manufacturing cannot change directions quickly or produce parts immediately. There is also the consideration of startup costs of a mold or tooling setup, these costs generally run more than $10,000. By comparison, digital manufacturing processes cost less to own or operate and can provide products and concepts in days versus weeks or months.

The COVID outbreak of late 2019 and early 2020 has shown us that our worldwide supply chain isn’t nearly as strong as we thought. The virus started in one of the largest manufacturing centers in the world and then made its way across all oceans and infected much of the rest of the planet. Worldwide manufacturing took a big hit when both suppliers and consumers couldn’t do their part in the economy. On top of this, the demand for certain products skyrocketed. With few producers open and operating, businesses were forced to explore new channels for manufacturing. Medical professionals and first responders were in need of common PPE items. Shortages of PPE have also affected grocery and essential retail workers who never had to worry about these concerns in a typical workday environment.

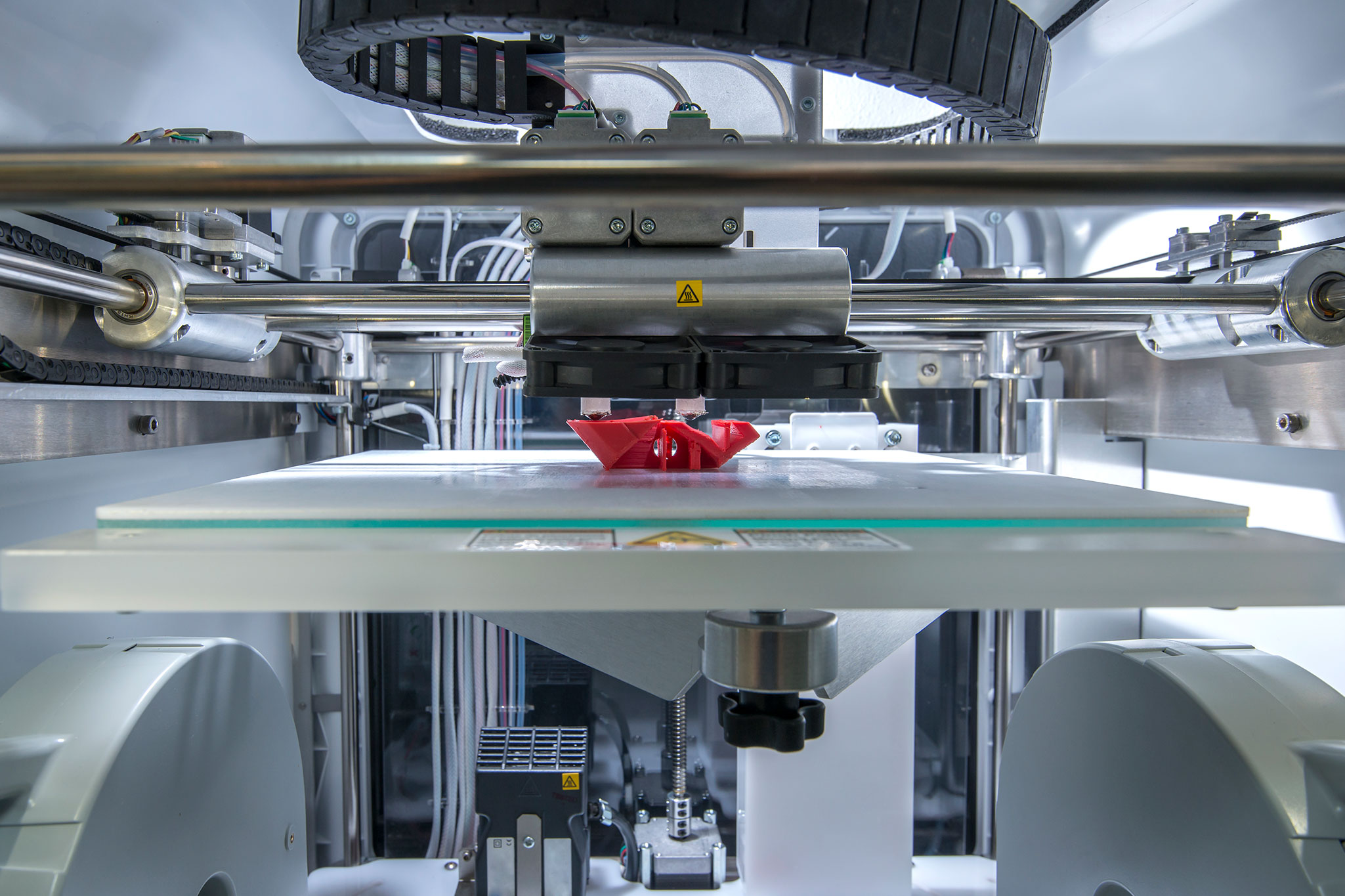

Enter 3D printing and additive manufacturing– two pillars of digital manufacturing. There are thousands of 3D printers all over the world and operators who are skilled in using them. The typical production “factory” went from a 100,000 square foot facility and moved into a 300 square foot garage. The literal scale of manufacturing changed overnight. This is the promise of digital manufacturing. This shows that even in the worst of times that there is still a network for production and an option to get things made.

Huge groups of makers, professionals, and others have banded together to digitally manufacture the needed products to face the COVID crisis head on. From face shields, to mask concepts, to mitigation tools, many of us have been thrust to the front lines supporting our healthcare workers with our efforts.. There have been thousands of designs all made with the unified purpose of slowing the spread of the virus.

Digital manufacturing has not only filled the gaps in the current supply chains. It has provided a level of comfort and support to customers because they know their products can be sourced locally and it’s easy to connect with the manufacturer. Far too often, manufacturing is done in different corners of the world, and there is no real connection between customers and how their products are made. Digital manufacturing gives consumers the confidence that their products can be manufactured just down the street rather than thousands of miles away. In times of crisis it is comforting to know who is making your protective equipment and where it is being produced.

Working with the right team in order to get an idea into production very quickly can be a big advantage during normal business, but in a crisis it is invaluable. The 3D Printing Store was fortunate to be a part of the movement of digital manufacturers who jumped at the chance to support our healthcare workers in their fight against COVID. 3DPS is printing thousands of face shields and other PPE items for many different clients all over the USA. Our work through the COVID crisis may be our most meaningful work yet. Our team worked around the clock to support those who were facing the crisis on the front lines and were inspired by their efforts. We thank each front line worker who sacrificed so much to protect us all.

3DPS has been a leader in digital manufacturing since 2012 and has helped people and companies develop projects and manufacture parts for many different needs. We know the potential of digital manufacturing and can guide you through the entire process. We know that manufacturing has evolved even more in the last few weeks in the face of this crisis. Let us show you why it matters and help you learn how you and your business can benefit from digital manufacturing. Whether your needs are– urgent or long term– we can help. We have been there and we will continue to be here for you. Get in touch today!