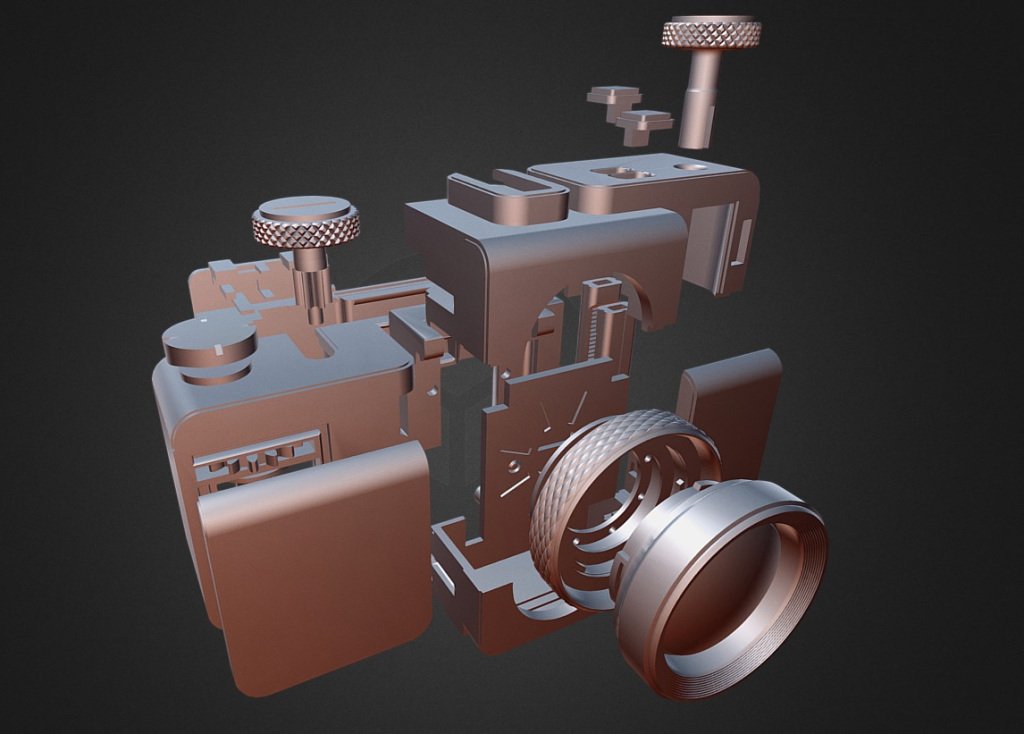

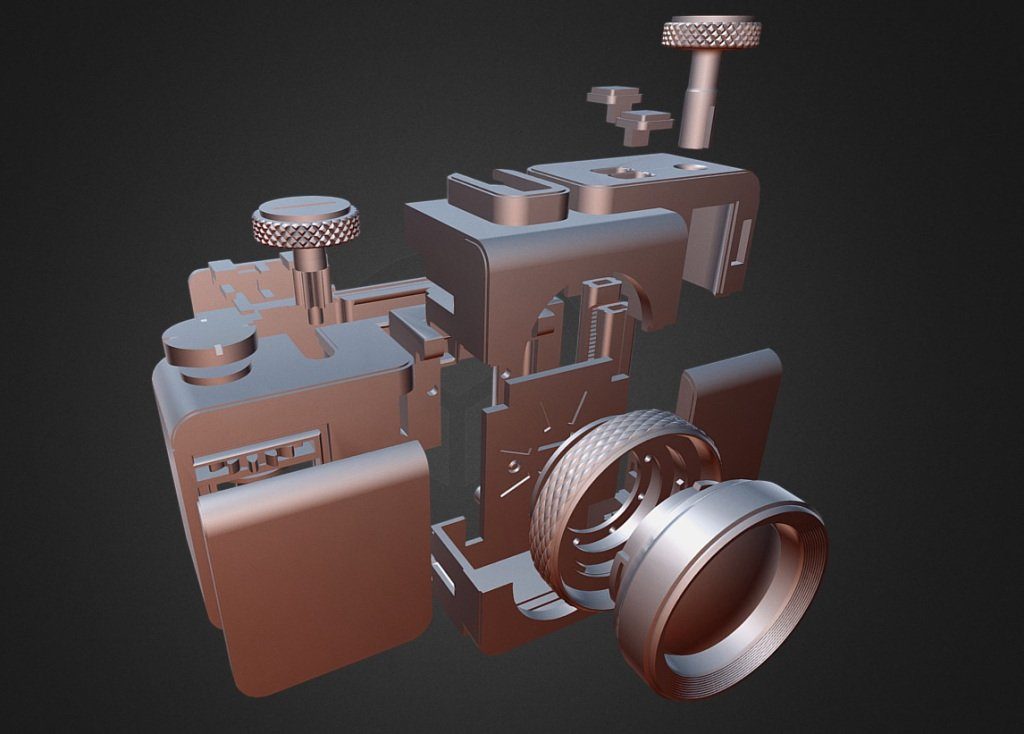

Here’s reverse engineering: a camera developed from a photo. That’s funny, but that’s the majesty of 3D Printing capabilities. In past case studies for 3D Print Camera devo, there is always prefabricated part filling out the component list: a hinge, a spring, or more complicated bits like shutters and iris mechanisms. In a story posted on TechCrunch.com, designer Amos Dudley made a camera entirely out of 3D printed parts — including the lens. We all know it takes photos of your component to build the file to use in 3D print. A file photo of a camera … that’s a funny twist to how 3D Print technology can bring dynamic manufacturing to your workplace. Behold the mold that can be produced in your engineering lab or your basement. This entrepreneur inventor used a Form 2 SLA printer, which can put out objects using a variety of resin types — a flexible one for one piece, a rigid one for another, a colored one for one piece, a clear one for another. It prints at a high enough precision (sub-millimeter) that things like small gear teeth or other interacting machine parts can be produced without the need to do lots of manual post-work knocking off pieces or sanding them down. This process forms the part from inside out, so precision is easily achieved; traditional molds take a mass quantity and carve to gain the subject matter.

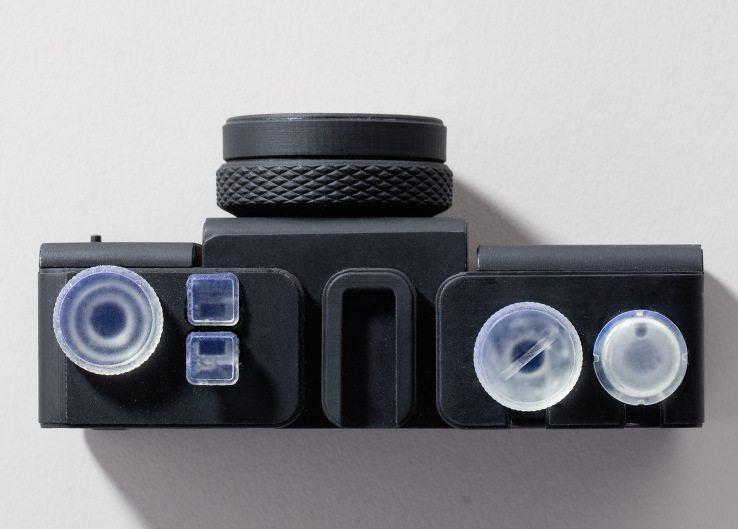

The enclosure, film sprocket and iris are all more or less straightforward — the latter has a rather organic look from the way its resin blades slide past each other.

For the shutter, Dudley rejected a few common mechanically simple designs and found a solution in a camera from 1885. Two mirror image planes swoop past one another when the shutter button is pushed, moving from blocking the aperture in one position to blocking it in the other — but while they move, the way is clear. In Dudley’s design, you end up having to press one shutter button to switch them one way and another to switch them back, and there are no set exposure times, but it works.

The amazing part is the lens. First Dudley worked out exactly what optical qualities he’d need, simulating the parts and distances involved in a ray tracer. Then he actually printed it out using a high-quality transparent resin and sanded it down with a custom machine. Then a dip in liquid resin fills in the tiny valleys and flaws, making the lens, if not optically perfect, at least functional. It’s spherical, so there are problems towards the edges of the frame, but with the aperture, limited and other factors accounted for in the body of the camera, it works!

Pop a little film in there (Fujicolor Superia 400 — can’t 3D print that… yet) and it’s ready for its close-ups. Because it has a fixed focus and not a very distant one.

To view more of Dudley’s photos, click on Dudley’s Flickr stream.

The specific specs for Dudley’s process for practice and the 3D models and other specs are available here.