The Big Idea: Print Farms, Metal, and ADAM

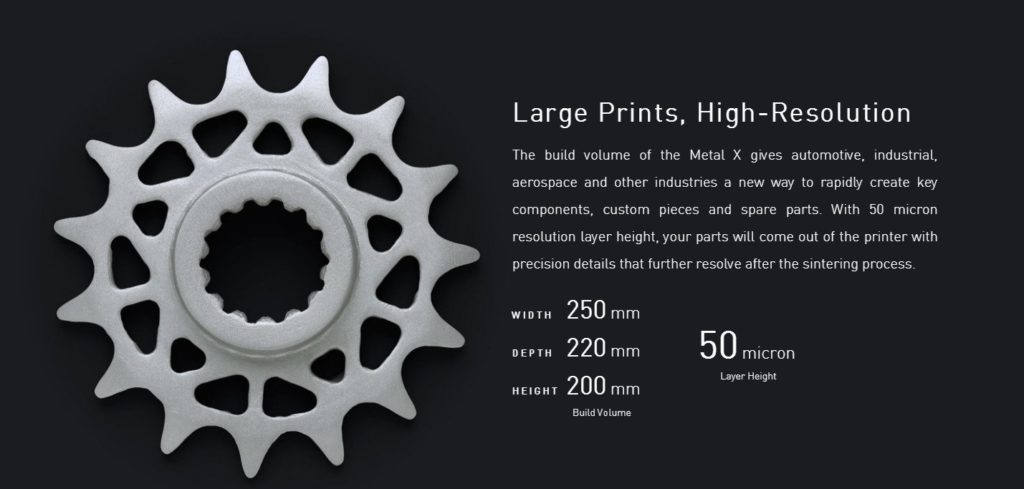

Markforged continues to blaze its own path in the world of 3D printing, first with the announcement and release of the first metal desktop 3D printer priced under 100K. More recently Markforged CEO, Greg Mark, announced that their latest endeavors focus around the concept of 3D print farms. Print farms are not a new concept by any means, but this concept has seen most of its application in the realm of plastic printed materials. Before delving too far into Greg’s latest endeavors, it’s important to spend a moment discussing why the Metal X is so revolutionary. The Metal X printer is unique not because of its ability to print metal, but more so for its ability to do so in such an efficient manner. Not only is the printer more efficient than pretty much any other metal printer on the market, it’s also compact enough to fit on your desk (more on why this is such an amazing step in technological advancement later in the article) The reason the Metal X printer has taken the print world by storm is largely centered around the process in which Greg and the team at Markforged have developed for printing metal materials. The process is called Atomic Diffusion Additive Manufacturing or ADAM for short.

Here’s the technical definition of ADAM from Markforged’s website.

“ADAM prints your part using a bound metal powder rod that transforms into a dense metal part in one easy step. Bulk sintering provides crystal growth through all axes giving your parts excellent mechanical properties in all directions.”

Still not sure what exactly is going on? Not to worry here’s a video.

Simple enough right? Where here’s where things get all rise against the machines… Fast forward to a few days ago in Greg’s latest press conference, he’s quoted saying “The future of metal 3D printing is in print farms.” The future of printing? Really? Yes! Here’s why… Mark states that the 3D printing and additive manufacturing industry has shifted gears from focusing on creating machines that produce one of creations in a somewhat efficient manner which is more of a short-term vision, to focusing on the large term which is to replace the current “analog” methods of metal production with a more streamlined and dare I say automated approach to metal production. This digital upgrade will come in the form of a concept discussed earlier, print farms. A print farm is basically a set of printers set up to run in parallel in order to produce a particular part or pieces that make up a larger part in a more efficient manner than the current production process in use will allow. For the team at Markforged, this shift in focus came internally first. Over the past months since the release of the Metal X printer their team has assembled a prototype “print farm” which has over 100 printers running in parallel. He goes on to explain that half of the printers are dedicated to producing parts for developing new printers (which is something that you could adopt yourself if you were to purchase a printer of your own), 30 printers are used for long-term cycle testing, and 20 are used in operations to manufacture sample parts.

How Markforged Print Farms Work

The Metal X printer farm concept will utilize the advanced smart sensors built into the machine in combination with Markforged fleet management software to control the workflow of the large the number of connected printers within the network. As mentioned earlier this is largely unthreaded water in regards to 3D printing metal, but the Markforged team did have previous experience in the form of plastic 3D print farms. Take for example Voodoo manufacturing, a New York-based additive manufacturing bureau, which has stepped up an automated FFF printer farm that now operated by an autonomous arm. Stay tuned as we continue to cover all things Markforged and provide you with all your need to know information about additive printing, prototyping, and large scale manufacturing Thanks for giving this article a read, if you enjoyed it feel free to pass it along to someone else. Featured images and video are from Markforged