Artec 3D Scanners: The perfect investment for reverse engineering

An international manufacturer and distributor of construction machine spare parts wanted to replace old parts with new ones milled from 3D models made by the Artec Eva 3D scanner.

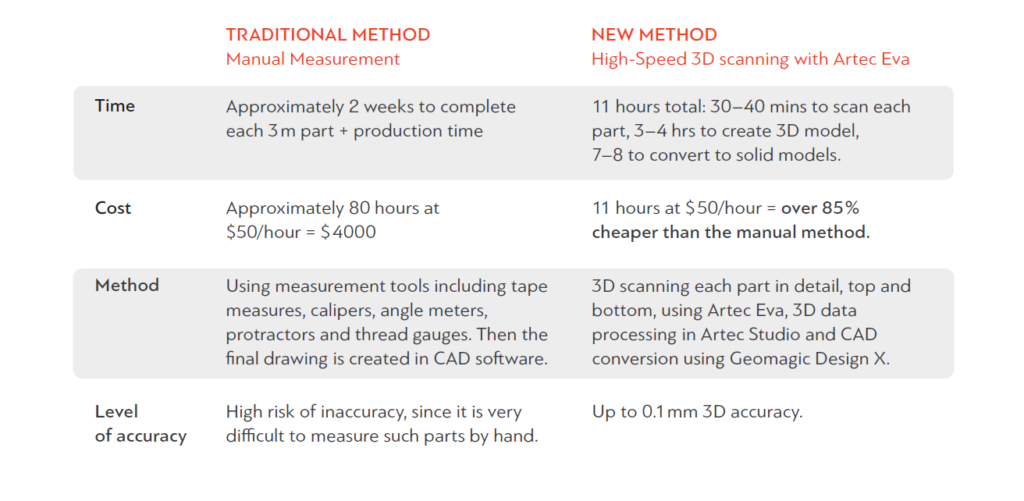

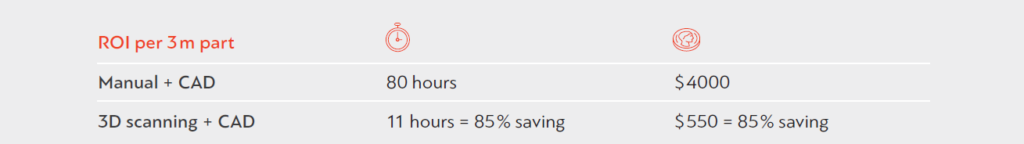

The company achieved over 85% reduction in time and cost using 3D scanning

Scan to CAD with Artec Eva, up to 0.1mm 3D accuracy

It was 85 % faster and 85 % cheaper to make these parts ready for manufacture, compared to using traditional measurement tools.

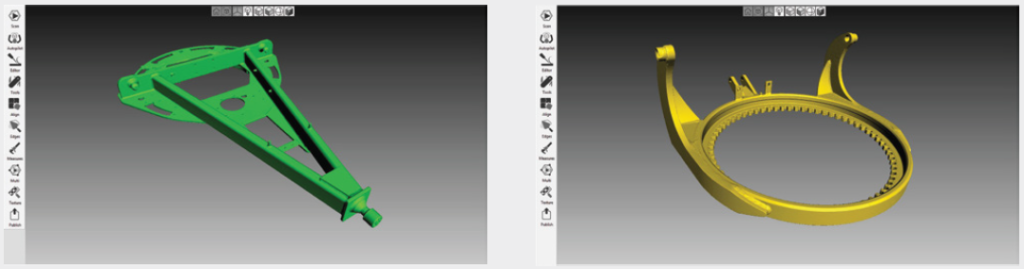

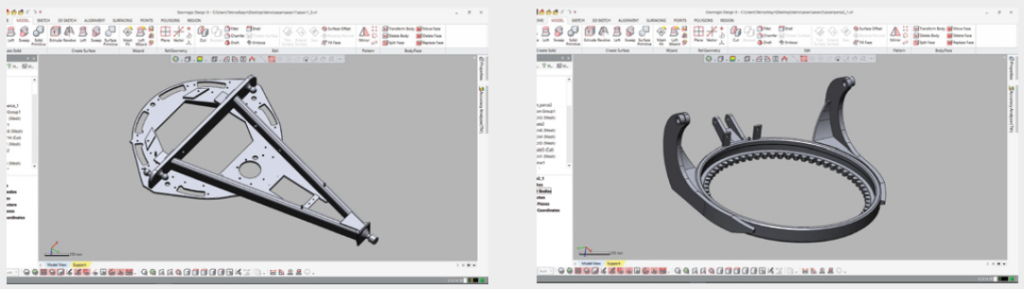

1. 3D scan all sides of your object.

2. Process the 3D data in Artec Studio and create a high precision 3D model.

3. Convert the mesh model into solids.

Other advantages of using 3D scanning: Accuracy

Measuring these kinds of large parts manually is very difficult, lengthy process and is likely to result in an inaccurate model as a result. 3D scanning, however, is much faster and simpler, and perhaps most importantly, results in a high precision 3D model which you can manufacture with confidence.