Dan Dement has been in the jewelry business for nearly fifty years, the last sixteen making custom jewelry for customers at his Stone Oak Jewelers store in San Antonio.

Being in Texas, Stone Oak specializes in bling. “Very few of our rings have fewer than 200 stones in them,” Dement explained.

Using traditional handcrafting methods, it would normally be difficult for a store like Stone Oak to compete with the Big Box retailers on the types of jewelry pieces popular in his market.

But Dement doesn’t use traditional methods. An experienced jeweler, Dement is also a self-professed “gadget freak,” and he has one of the most technically advanced operations around.

Stone Oak uses the latest design software and an EnvisionTEC Perfactory 3 Mini Multi Lens 3D printer to make accurate, detailed jewelry patterns, which are then used to make an investment casting that produces high-quality, finished jewelry for his customers — within a week.

“A handmade jeweler can’t achieve what we do in a typical piece,” Dement said of his high-tech operation. “Can you imagine asking a jeweler to sit down and make a piece that has 200 stones and 800 prongs and make them all exactly the same?”

While Stone Oak offers jewelry in a full range of metals, about 80% of its custom- made jewelry pieces are palladium, which is in the platinum group and regarded as one of the more difficult metals to cast. But Dement finds that his EnvisionTEC 3D printer produces models in just the right low-wax polymer to develop a high-quality investment casting with exceptional detail. That, in turn, delivers exceptional final results.

“Highly talented jewelers want to believe that handcrafting a complex ring from eight or nine or ten pieces is the only way to do it,” Dement said. “That’s wrong, and in my opinion such a ring is not as good as a solid casting. CAD and the ability to grow the model and cast it in one piece give you a much more solid ring without putting a million hours into it.”

Industry Experts Explore the Possibilities

Dement’s experience with 3D printing started about ten years ago when Dement visited GemVision, the world leader in CAD/CAM tools for jewelry, both then and now. Dement had provided diamonds to GemVision for use in promotional films and wanted to check out their operation.

Immediately, the technology-lover became intrigued by the company’s equipment and rapid prototyping processes.

GemVision’s Travis Serio — “the most knowledgeable guy in rapid prototyping machines,” Dement said — told Dement he thought he could direct cast platinum and palladium with EnvisionTEC’s equipment and resins.

“Nine years ago, no one knew how to do this,” Dement recalled. “Against everybody’s advice except Travis’, I went on the quest of being able to direct cast platinum, palladium, and even rhodium.

“I got an EnvisionTEC Mini machine, and I was able to direct cast these metals using their PIC-100 resin for the patterns. We’ve been doing it now for nine years.”

Quality 3D Printing Materials Matter

In order to develop a quality investment casting, which leads to a quality final product, Dement said jewelers need to use the right technology, materials and take the time to understand their features, properties and the trade-offs.

Dement said Serio was using a low-wax polymer to build his detailed patterns. Dement caught on, explaining, “it’s easier to cast resins with a big wax base, but a bigger wax base doesn’t allow you to get the detail you can get with a more plastic- like resin. The less wax, the more detail you can model.

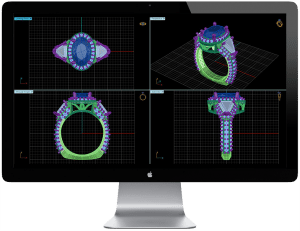

After a friendly consultation, Stone Oak Jewelers starts all of its custom projects by designing the metallic portion of the piece using CAD software. Next, they’ll show the customer a 3D wire frame preview from all angles.

“Almost all of our rings have dozens of diamonds, complicated galleries, and many other features you just can’t get with a wax-based growing material. We’ve stuck with EnvisionTEC’s PIC-100 resin. It has always worked very well.

“Our precision is pretty much dead on. We don’t have a lot of shrinkage or expansion the way we do it. We don’t have a problem with it when we’re measuring diamonds and so forth. It’s pretty much exact. You hear about people who have to scale up their materials 3% or scale it down 4%. We don’t do any of that.”

On the other hand, other adjustments are sometimes needed. For example, Dement said, “Higher resolution resins expand when you burn them out and this can crack the investment, especially in a bigger ring. You also have to heat your oven to fourteen-hundred to fifteen-hundred degrees Fahrenheit. So we ended up getting a special, super hard investment for our work. It’s harder than concrete.”

The system delivers exceptional results.

Understanding Materials Extends to the Metals

Understanding the materials used for 3D printed models, Dement said, is just as important as really understanding the scientific properties of metals and how they cast differently.

“The business has gotten much more technical and it’s what you have to do to stay ahead of the game,” Dement explained.

By mastering material properties, as well as the technologies offered today, Dement and Stone Oak Jewelers have found a way to stay ahead of the competition.

After a client visits to discuss a new jewelry concept, Stone Oak uses GemVision software to create a 3D model within a day. On any given night, the team may send 20 custom models to the EnvisionTEC Mini to be printed. The next day, they can then show the resin model to the customer, allowing them to try it on or make modifications.

“If they like it, we invest it and cast it and they can see it in metal the next morning,” says Dement. “Then depending on how complicated the piece is, it takes us two to three days to get it finished. So we strike pretty quickly. A lot of jewelers take four to eight weeks. That’s significant, because in the jewelry industry, if you give customers too long to think about it, they change their mind and want to make changes.

“We made custom jewelry for six years without 3D printing. So we know it’s much more profitable to do things this way. If something doesn’t come out right, or the customer does want to change something, you just make the change [to the digital model], grow it, cast it, and get on down the road. You don’t have a gazillion hours times two into the job.”

Once a customer has approved the design, Stone Oak sends the CAD file representing the metallic portion of the piece directly to the EnvisionTEC Mini machine, which prints a highly accurate version of the jewelry in PIC-100 resin in a few hours.

The next day, Stone Oak casts the piece in the desired metal. After finishing, Stone Oak presents a delighted customer with the finished, custom jewelry.

Minimizing inventory also contributes to profit

The 3D printing model also allows Stone Oak to combat one of the industry’s longstanding challenges – the high cost and low turnover of inventory.

“We have 200 sets in our cases, but we still end up making 95% of what we sell in any given year,” Dement said. “It doesn’t matter what you make or buy, you’re never going to sell half of it through the year. We make up some silver and cubic zirconia samples of things we’ve made in the past as show pieces. But we don’t have to invest in new inventory. The ability to design a new piece, make it, and have it on your finger in a week, eliminates the need to pour money into inventory.”

Ultimately, a digital manufacturing system has enabled Stone Oak to compete more successfully. Dement recently sold the successful business to his son-in-law, Mike Bowling, who has been with the company for years.

“Big stores don’t want to go up against us because they buy everything in China and can’t customize anything,” he said. “We’re also fighting internet merchants selling basically brown, grainy, milky diamonds. But I don’t see how little shops can survive today without going the route that we have gone.”

“Even with the Texas oil business suffering, we’ve been able to maintain our sales volumes and improve our profitability. Everyone else I talk to is behind last year.

“So I think the proof is in the

pudding: Digital manufacturing works for us.”

3D Printing and Casting Tips from a Pro

Dan Dement of Stone Oak Jewelry in San Antonio, Texas, has tips for casting platinum group metals with 3D printed models.

First, Dement said jewelers need to drop their reliance on tradition. “Jewelers want to do it like they’ve done it for the last twenty or thirty years and that’s not necessarily what works best,” Dement explained. “What works for silver doesn’t necessarily work for gold, which doesn’t work for platinum, and doesn’t necessarily work for palladium.”

Take milgraining, that row of tiny beads or hemispheres along the edge or boundary of a section of jewelry. “A lot of guys say they only want to milgrain by hand,” Dement said. “We grow our milgraining with the EnvisionTEC. It holds up better when you cast it in rather than try to put it in by hand. But some jewelers think you worship the devil when you take these shortcuts. Most jewelers are creatures of habit, and often their own worst enemies.”

Above, an example of the type of custom work a digital system enables at Stone Oak Jewelers in San Antonio, Texas. The jeweler uses GemVision CAD/CAM software, an EnvisionTEC 3D printer and quality investment casting.

Second, Dement said jewelers need to invest in the right equipment to get quality results. “Our EnvisionTEC machine was $80,000 back when we bought it and it’s still going strong,” he said.

“The better machines just hold up,” Dement said. “We’ve run it almost every night for nearly ten years and had only one service call that whole time. Everybody today wants to buy a cheap machine. Well, that’s kind of like having a pickup truck. If you’re trying to pull a 40-foot trailer that’s maxed out, a quarter-ton truck ain’t gonna last.”

The same goes for Stone Oak’s casting machine. It was $40,000. “That’s pretty much how we do everything, across the board,” Dement said. “We’re always at the top edge of technology and trying to find the best people.”

Third, follow best practices and keep your eyes open for new technical advances.