Original article appears on www.ITPro.com

What is 3D Printing?

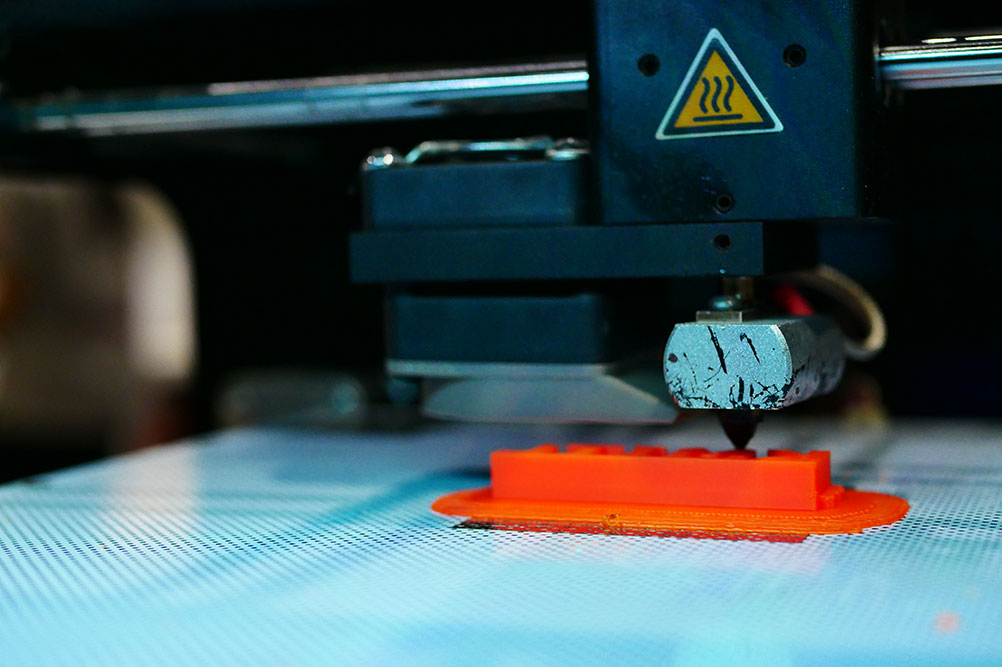

Are you having a hard time understanding what 3D printing is and how it can benefit your business? We’re here to help! 3D printing is the manufacturing process of converting digital blueprints into physical objects. Printing in 3D happens in much the same way as traditional printing – instead of a text file, a digital schematic is used to map out a physical object, which is then built up layer-by-layer using a variety of materials. This process is regarded as ‘additive’, whereby the object is created using only as much material as is required for the job. Compared to processes that machine an object down into something usable, this massively cuts down on waste. Aside from this basic principle, technology dictates how 3D printing is applied in industry. Desktop printers will use plastic toners, which are melted down and then laid out onto a designated platform, while larger industrial printers make use of metal powder that is selectively targeted with high-heat lasers. Rubber, metal alloy, sandstone, and even meat-based products can be used as materials – and the list is constantly expanding.

Is it Popular?

Although 3D printers remain some way off becoming an everyday consumer device, the technology is no passing fad. More than 278,000 3D printers were sold worldwide in 2015, according to the latest Wohlers Report – almost double that of 2014. In the last two years, 3D printing sales have grown by 99%. The additive manufacturing industry has seen a growth of 25.9%, surpassing $5.2 billion in revenue. Although the total number of sold 3D printers may seem relatively low, the majority of current customers are within large companies and startups with big pockets. Where is it used? So far, the technology’s biggest successes have been in industrial applications. It is extensively used in car manufacturing, particularly higher end prototype products or Formula 1 racing, where its customizability is seen as a strength. Aerospace pioneer SpaceX is able to create engine parts using 3D printing without the substantial lead times that traditional processes place on deployment, speeding up the process dramatically. And the field of architecture has been transformed through the use of 3D printing, where individual architects can create scale models directly from their own CAD designs, instead of using artists. Engineers, prosthetic designers, shoemakers, and even drone hobbyists are taking advantage of the flexibility that 3D printing affords.

What are its Benefits?

As the finished product is 3D, the technology allows designers to create complex shapes and intricate parts that would otherwise be too delicate to produce conventionally. Complexity in design adds no extra cost to additive processes, making it possible to work around current limitations. Printing schematics act like normal files, which can be shared between computers and printers. So long as you have the correct toner to create the item, the printer files, such as spare product parts, can be downloaded from websites and sent straight to the printer. The entire process is also highly cost effective, which is particularly useful for startup businesses looking to prototype new designs on small product runs. Design changes can all be done within the schematic, avoiding the need to contact manufacturing plants to adjust the blueprint.

What are its Drawbacks?

Most drawbacks are due to the infancy of the technology. Although the list is expanding, you are currently restricted in your choice of materials and colors. Most consumer parts are printed in grays or whites before being painted by the user, and the finished products lack the strength associated with traditional manufacturing. Precision is also somewhat limited, as 3D printing is unable to produce the wafer thin designs that some products require.