3D Printer Filament Buyer’s Guide

Ultimate 3D Printing Materials Guide

The Pros & Cons of Different Types of 3D Printing Filaments

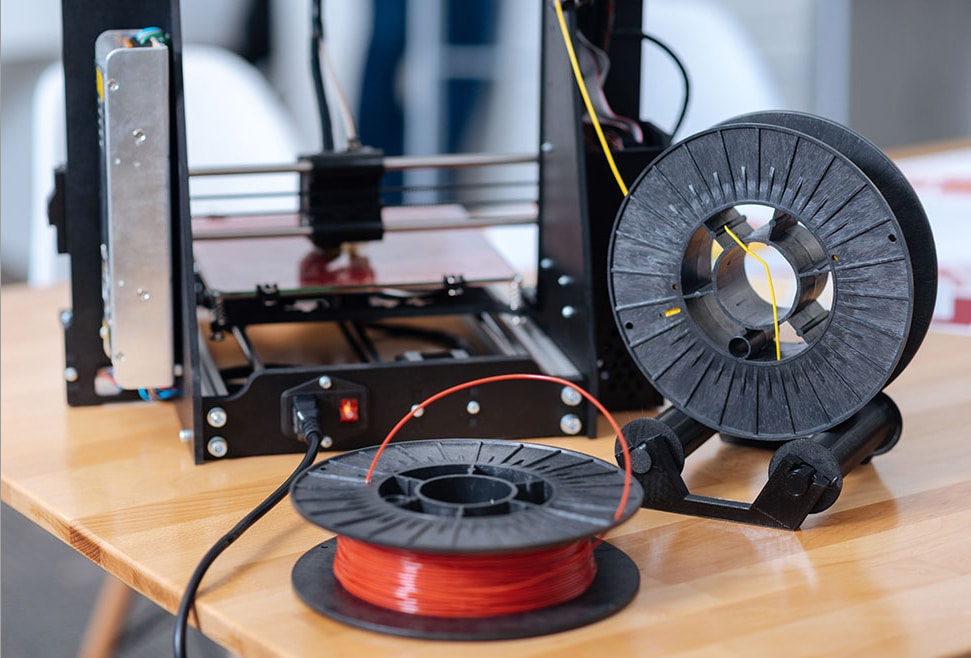

Covering some of the most popular 3D printer filaments in use today, this guide is designed to help you select the best material for your upcoming 3D printing projects and to improve the overall quality of your prints. We will be discussing the pros and cons of different types of 3D printer filaments, as well as covering different types of materials you can use, their parameters, and their main applications.

Due to the massive growth in popularity of 3D printing in both industrial settings (such as in the manufacturing of medical devices and consumer goods) as for home designers, the need for 3D printer support, guidance, and troubleshooting has risen in kind. The 3D Printing Store (3DPS) engineers and technical experts have 30+ years of combined experience in this field and have hands-on experience with more than 100 different types of 3D printer materials. If you would like personal guidance with what type of filament to get for your 3D printer or required professional 3D printing design services, repair services, at-scale additive manufacturing services, or 3D scanning services, our 3D printing experts (based in Englewood, CO and Richardson, TX) are here to help. Contact our 3D printing bureau today to consult with us for all your 3D printing needs, or shop filaments today!

Need help choosing the right filament for your 3D printing project?

How to Choose the Right 3D Printer Filament

If you are a new 3D printer owner, the first decision you will have to make after purchasing your 3D printer is what type of filament you should use. There are dozens of different types of filaments out there, and it can be a bit overwhelming at first glance. However, don’t let that discourage you, as there really are only a handful of filaments beginners will start out with.

What are Filaments, Anyway?

Filaments are types of thermoplastics that melt instead of burn when heated. Because of this, they can be molded and shaped when hot, then, when cooled, solidify into whatever desired shape you print. Filaments are fed into the heating chamber of a 3D printer, extruded (i.e., squirted) out through a metal nozzle, then traced, layer-by-layer into the printed object.

4 Common Filaments Compared

• PLA (Polylactic Acid) — This is a thermoplastic made from renewable resources such as corn starch, sugar cane, and tapioca roots, that is popular today largely due to the fact that it is not made of petroleum, like many other materials. It is a type of plastic that was originally developed in the 1930s that today is a popular choice for beginners in 3D printing due to its ease of use. It has a melting temperature of 180ºC, which is lower than ABS’s 200ºC to 260ºC melting point. The use of a heated printing bed is therefore necessary for PLA. It also lacks any major mechanical complexities, such as post-processing, so it’s a great material to work with when you are learning how to 3D print.

• ABS (Acrylonitrile Butadiene Styrene) — This thermoplastic polymer is also very common for 3D printing. It is best known as a great choice for a polymer that has good impact-resistance at low temperatures and that produces products with low weights. The most famous examples of ABS are LEGO bricks. It is also used to produce decorative materials and more. The 3D Printing Store sells the two diameters of ABS available — 1.75mm and 2.85 mm in spools ranging from 1kg to 25 kgs. Because the extrusion temperature needs to be between 230°C and 260°C a heating plate is required. Due to the fact that ABS can warp or shrink when it comes in contact with air, it is advisable to use special adhesive lacquer. It is also advisable to use an enclosure, since some of the plastic particles the 3D printing process emits with ABS can be dangerous to humans.

• PETG (Glycolized Polyester) — PETG is a thermoplastic that is very common in additive manufacturing. It combines the simplicity of PLA with the strength of ABS. PETG is the same material used in the manufacturing of food bottles. It is well-known for its impact resistance, transparency, and dimensional stability. It takes moisture well and keeps well in a cool, dry environment. However, PETG has a sticky appearance, which can make printing more challenging, and it also costs more than PLA and ABS.

• ASA (Acrylonitrile Styrene Acrylate) — ASA is similar to ABS, with the main difference that it is made of a petroleum derivative and has better resistance qualities. For this reason, it is used in applications such as electrical installations and for car parts, where thermal- and weather-resistant qualities are more essential. ASA is extremely versatile, but requires higher-quality 3D printing parts to produce reliably.

Contact Us

"*" indicates required fields