Recently, 3DPS spent a day with a global audience assembled for the #ADDITIV 2021 Aerospace Event. The panels were valuable to listen to and the audience was engaged. Aerospace continues to dominate the conversation for applications of additive manufacturing parts for airships, propulsion systems, rovers, and more– all parts of large projects going to space today or in the immediate future. The list of parts that can be 3D printed using some of the new composite materials and the super alloys is changing some of the conventional wisdom on how to make both rockets and their cargo.

There are many essays, panels, speakers, and virtual conversations about the impact of 3D printing particularly in the aerospace industry, but it is not fully embraced. There are still many questions that are being answered by experts, companies, and amateurs alike. There is still a lack of standards for both materials and processes. 3D printing standards, as they have been developed, tend to be specific to a particular company and even a specific part. This means that there are many standards and ways of making “certified” parts. With both NASA and commercial space using 3D printing to move the process of new parts and pieces along more quickly, we are no longer willing to wait for testing of parts that used to take months or years. The 3D parts that are on the Perseverance Rover demonstrate the speed that 3D printing brought to the final assembly of the rover. There are final parts on the Rover that were successfully printed and are now performing as planned on Mars.

It is debatable if this level of use of this technology would have happened even 10 years ago. The platforms, techniques, materials, software, and computer simulated testing have moved very quickly during the last 10 years– and even more rapidly over the past five years to make some of these advancements possible. There are also more qualified experts now that are able to both validate and explain the methods with the materials and testing to provide the level of assurances needed for the aerospace industry. Some of this expertise has developed rapidly and some of it has come from outside the mainstream aerospace industry. The democratization of 3D has brought to bear many disciplines and also challenged what we thought were unbendable principles of physics, chemistry, and material sciences.

Slade Gardner is a recognized expert in 3D printing, Lockheed Martin Fellow, and founder/CEO of Big Metal Additive. He recently noted the important role that aerospace has played in the development of additive manufacturing. They had the resources to commit to educating the workforce to use this technology. Slade has the vision of what is needed for the ongoing success of additive.

“Every discipline is involved in additive,” he said. “We need people of all backgrounds and educational skills and capabilities now because the additive market is growing so fast.”

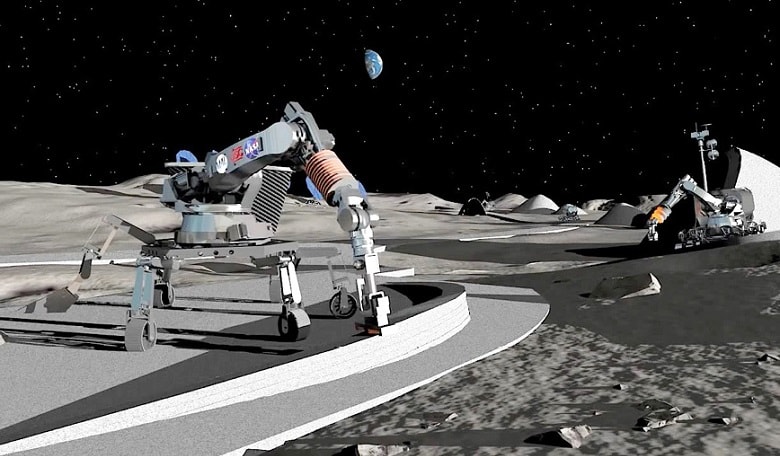

We will still see rocket technology developed over 40 years ago being used for the near future. However, we will also see fully 3D printed rockets, rocket engines, and different means of propulsion that were not pursued in the past. They are already quickly becoming an important part of our space industry. There will undoubtedly be more and as we look to long term space travel and possibly colonization. We need to think about these technologies as absolutely essential.

As always, The 3D Printing Store team is available to provide demonstrations, professional development courses, and educational courses to you and your team. Contact us or email arausch@the3dprintingstore.com for inquiries.