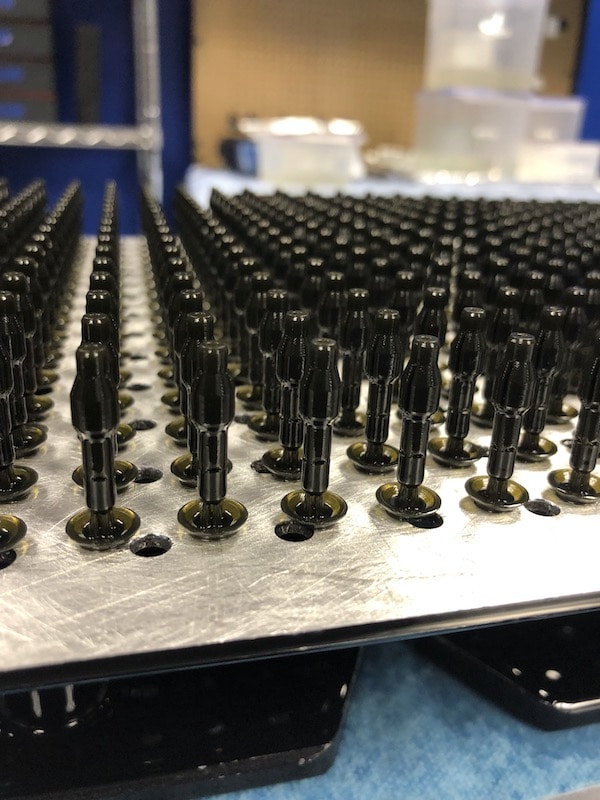

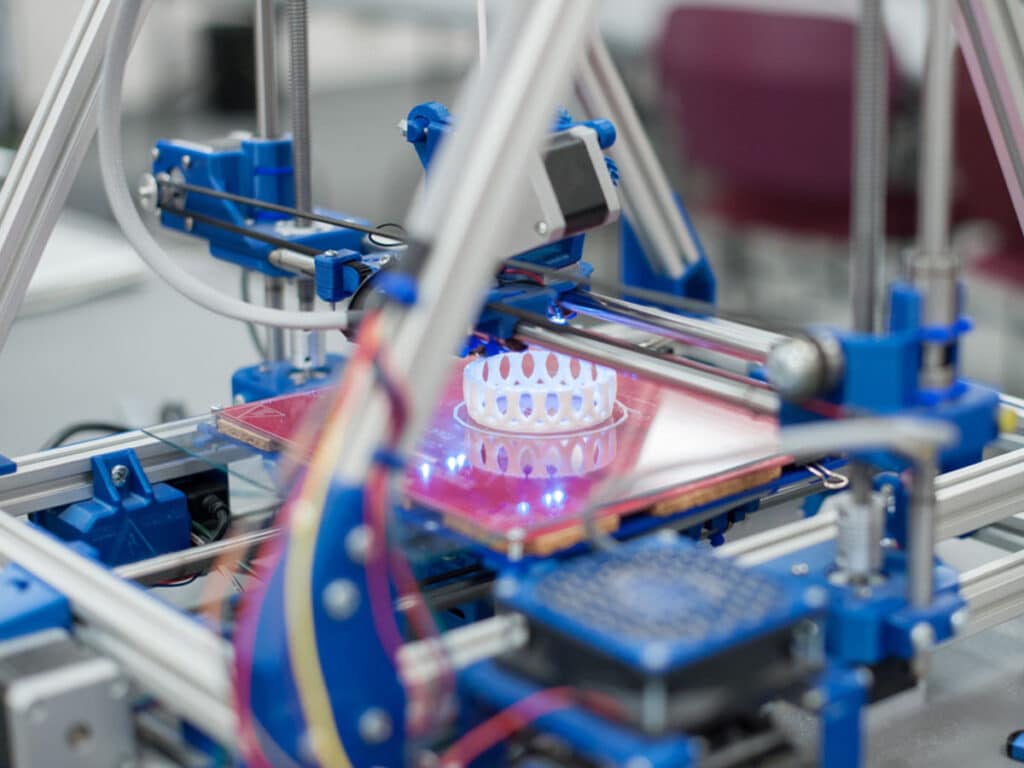

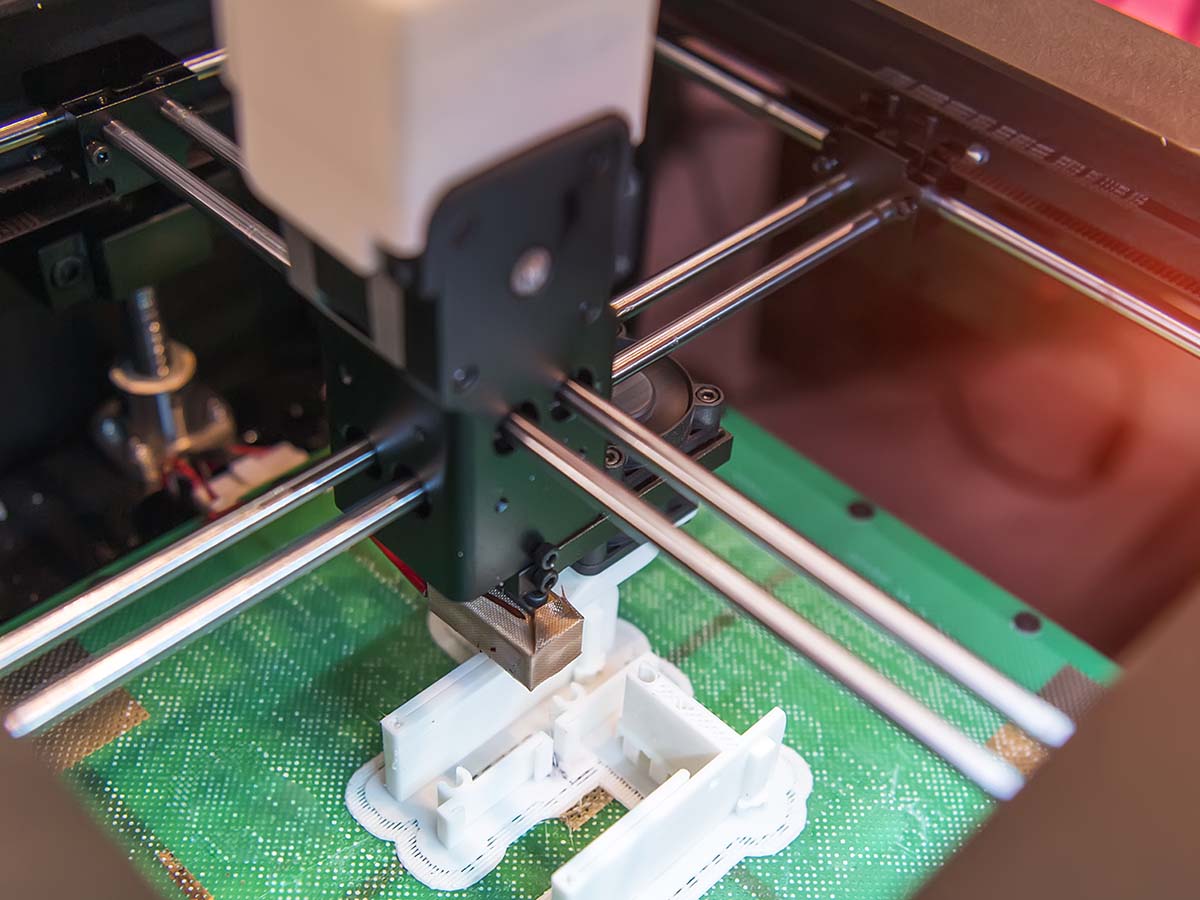

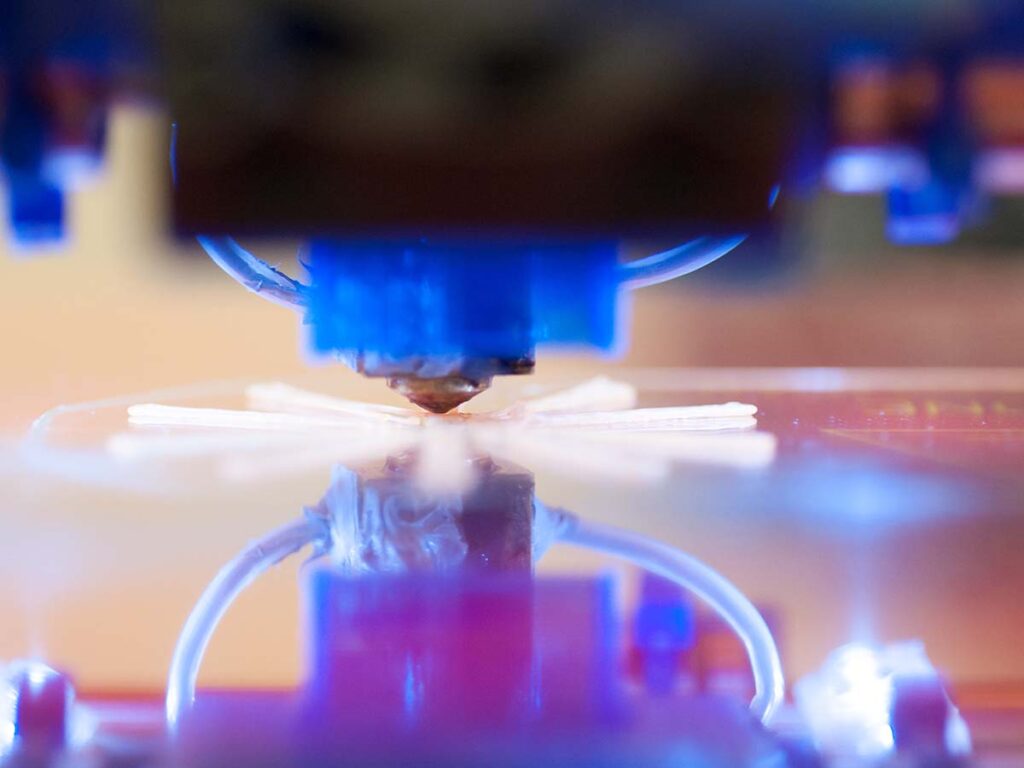

The 3D Printing Store (3DPS) used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser – which helps other entrepreneurs start their own auto glass repair businesses – to develop a part for its repair kit system. The proprietary technology helped Crack Eraser solve a challenging aspect of windshield repair, that of drilling into the top layer of laminated windshield glass at the point of impact where damage occurred. Using Photocentric LC Magna, 3DPS was able to manufacture over 1,000 drill collets, within acceptable tolerances, in just five hours of print time.

The precision 3D printed component, now known as the Drill Stop Collet, is used to hold the tiny glass drill used in windshield repair, and it has made this critical drilling process quick, reliable, and automatic. In the past, learning the correct technique required training, lots of practice, a high degree of fine motor skills and a lot of time to complete a repair successfully. The new part has simplified the job and enables Crack Eraser customers to make the perfect drill hole every time.

The 3D Printing store said that Photocentric technology was essential in both the rapid prototyping and production phases. They were able to print multiple drill collets to test the depth the drill bit would rest in each collet, and assess whether it was leading to a successful windshield repair. Once the design was finalized, production was fast and post processing was minimal.

Crack Eraser offers professional windshield repair kits, video training, expert support, and supplies. Owner Tim Evans has been in the business for 38 years, and he has continued to innovate and develop his own tools and processes to ensure the best outcome. Its kits have been designed to repair chips and long cracks in windshields up to 24 inches. Crack Eraser is the only company offering a proprietary 3D drill stop collet in every kit, marking a key point of difference from other competitors on the market.

“It’s very encouraging to see an innovative entrepreneur like Tim solving challenges by using additive manufacturing technology,” says Sally Tipping, sales director at Photocentric. “With LC Magna’s large build volume, it’s an excellent choice to produce end-use parts quickly and efficiently at scale, delivering speed, volume and cost savings to businesses. The intricate nature of this part means that precision tools are required, and in this case, LC Magna has been able to provide an agile and flexible solution for manufacture.”

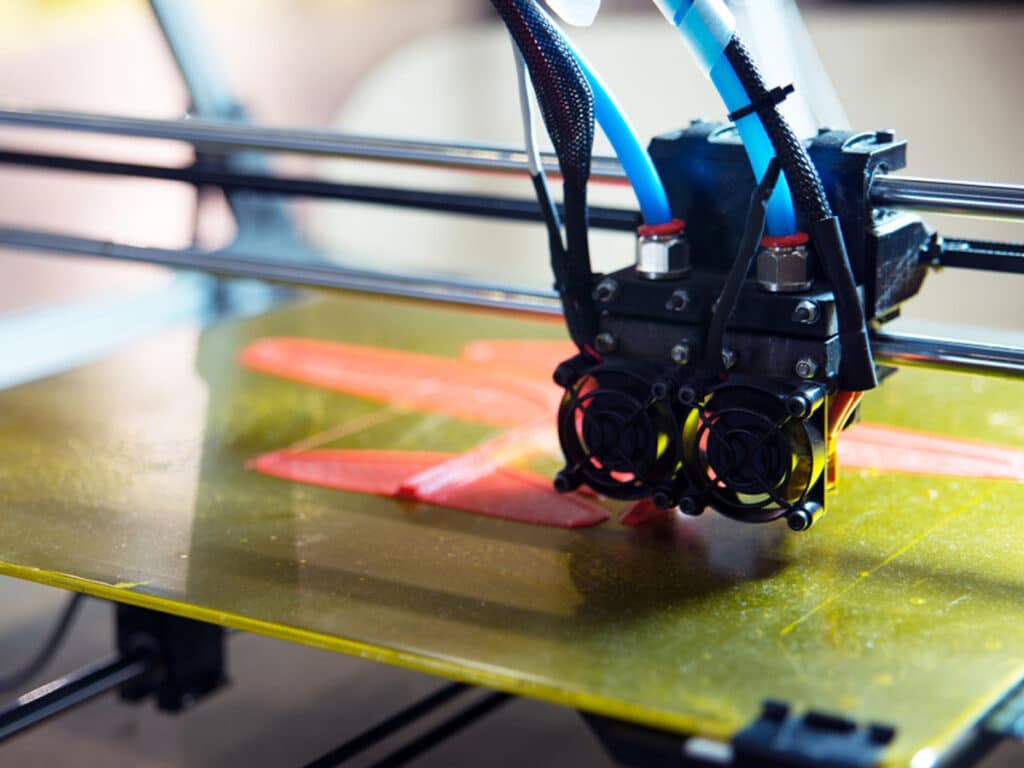

It’s crazy to think that a device used for so many top-tier engineering projects and campaigns is now a growing household item. We’re not saying that the next moon mission will be drawn at your home, but the utility provided from 3D printers is universal to all environments, given the proper knowledge and skill. The 3D Printing Store is all about how this great tool is used every day in the lines of aerospace work.

Part Refinement

Buttons and switches really can be the worst when it comes to breaking requiring replacements. 3D printers have been able to cut out the expensive middleman of (sometimes) obscure shopping for parts. The growing community of engineers online sharing their work, insights, and schematics has helped the field tremendously when it comes to getting the replacement needed for a large-scale project.

Structural Functions

Manufacturing brackets for aircraft quickly comes to mind when thinking about the utilization of 3D printers for aerospace. Being able to upload model data of specific crafts into a computer and then build new parts for 3D printing has helped streamline the production process tremendously. The added value comes from the ability for multiple engineers to look at your rendered model data and add their input for refinement in the drafting process. No matter your connections or experience, The 3D Printing Store has the information you need to get started on like-minded ideas.

Interior Design

Being able to layer upon a foundation to tailor to said space is a vital aspect of aerospace design. 3D printers have opened the floodgates for streamlining ideas and building upon them quickly for desired results. Incredibly, someone at NASA can now have an expert be away from work and still create a new interior design to send remotely in record time. The 3D Printing Store recognizes and fully supports that innovative strength by always being supplied for these swift demands.

Innovations Through Experimentation

There’s a beauty of value in being able to fabricate and test new concepts without much financial repercussion. The expanding working foundation from 3D printing has allowed faster communication and experimentation for developing ideas in the aerospace field.

3D printing is the future. Both the professional and casual markets have seen a tremendous increase in producing new concepts and ideas at a breakneck pace. The 3D Printing Store wants to hear about your visions and ideas, so contact us today!

The aerospace industry is constantly changing with new technologies and (expensive) ideas. Thankfully the 3D Printer was designed to be adaptive with the times as it constantly caters to the boundless imagination of its collaborators. The 3D Printing Store recognizes the important demands that the aerospace industry has and what 3D printers can do to meet them every day.

Efficient Communication For Faster Results

The 3D printing community is a broad term that covers a plethora of engineering disciplines as well as artists. From articles to public forums, the process of asking a modeling question and getting an educated answer has never been more efficient.

Quick Editing

Just like word documents, 3D printing schematics make it easy to edit or re-do functions that aren’t needed. Being able to brainstorm and alter plans quickly in the aerospace industry is vital for productive momentum.

Affordable Additions & Replacements

The parts and products you can make in a 3D printer compared to the upscaled prices in the past are staggering. Rather than having to find custom-tailored parts from niche manufacturers, you can combine your resources of data with flexible materials and save money in the long run. This also includes the usefulness of having past model data readily available should a replacement be needed down the line.

Increasing Usage Worldwide

Not only are 3D printers being added to more homes, but businesses and universities as well. The increase in educational material for future generations has only increased the usage and skills for 3D Printing. More companies each day are recognizing the importance of 3D modeling and printing as they look for new employment opportunities in the aerospace industry.

The 3D Printing Store’s 30+ years of experience with our cutting-edge design tools is something that we want to use to help others. Get a free consultation today!

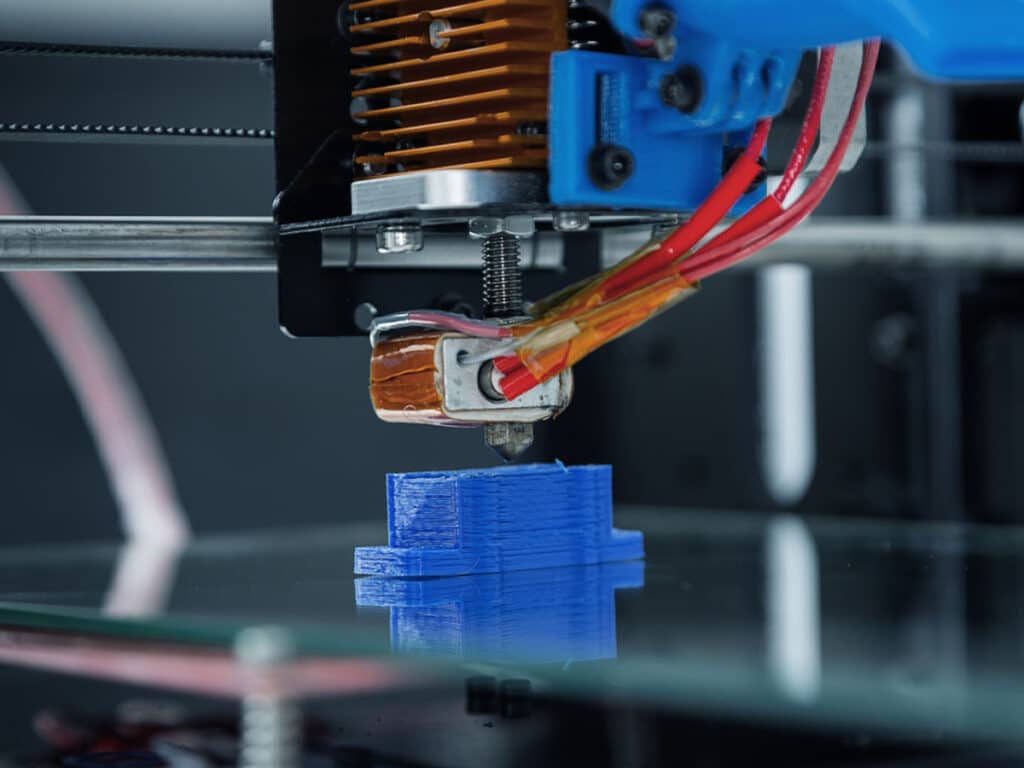

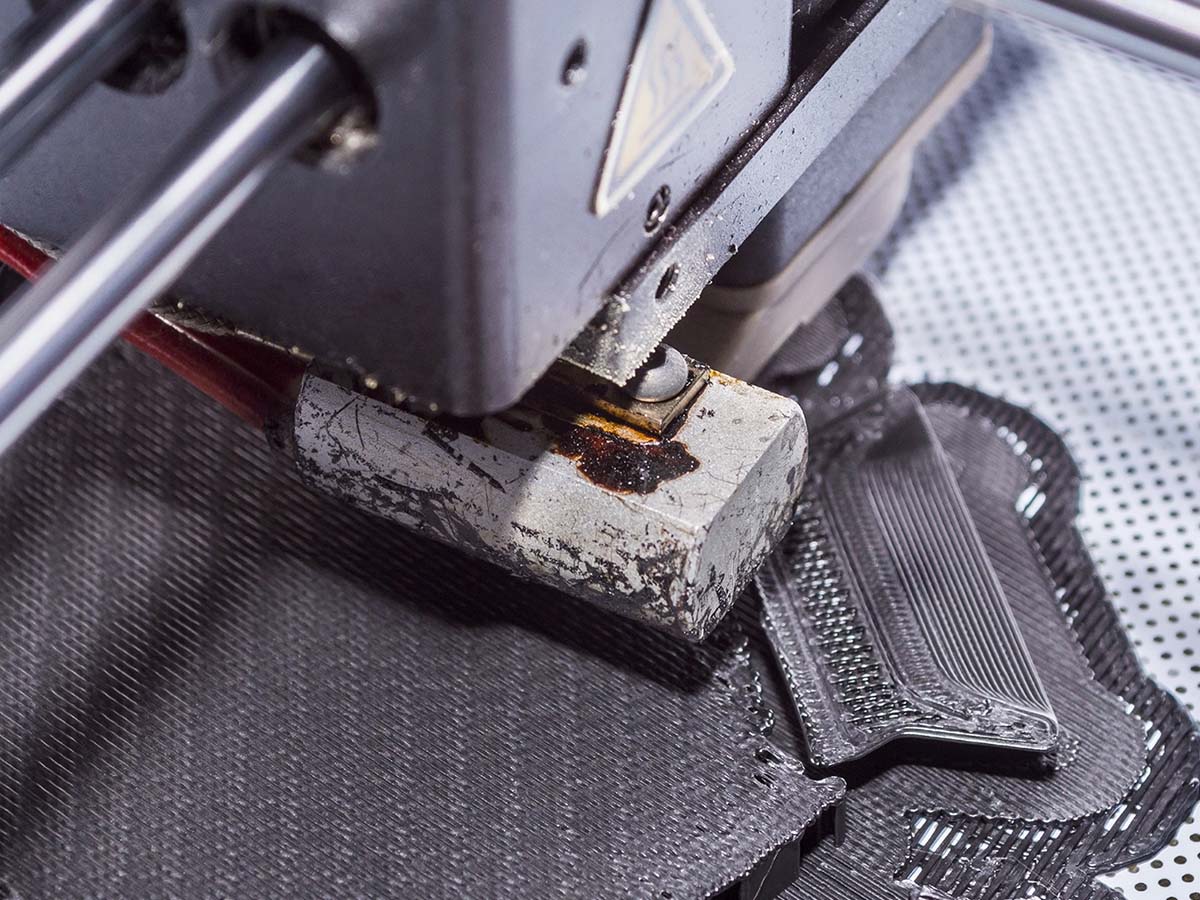

There are a number of reasons why you should have your 3D printer repaired as soon as possible. 3D printers are complex machines, and they can break down for a variety of reasons. We have listed four of the most important reasons why you should have your 3D printer repaired as soon as possible. Contact the 3D Printing Store in Denver, CO, and Dallas, TX, for on-demand 3D printer repair services today!

Less Expensive Than Buying a New Printer

3D printer repair is less expensive than purchasing a brand new model. At the 3D Printing Store, our repair services start at only $99.99! Compared to other 3D printer repair companies, our price is the best deal around. This cost includes a 20-point inspection, a complete rundown of our diagnostics, a free test printer and slicer to give you a reference for any adjustments needed, and a comprehensive report with our recommendations.

Extends the Life of Your Printer

Having your 3D printer repaired by the 3D Printing Store can extend the life of your printer. If you have a 3D printer that is not working correctly or if it is old and outdated then you may want to consider having it repaired. By repairing your 3D printer, you can prolong its life and use it for many years to come.

Restore the Printer to its Original Condition

By repairing any damage to your printer, you can restore it back to its original condition. If your 3D printer’s filament is not fitting, the printer won’t turn on, if there’s not enough plastic on your first layer, or it’s overheating, then you may want to stop by the 3D Printing Store to have it repaired. Our technicians will be able to repair your printer in no time, leaving it in like-new condition.

Improves Your Printing Experience

The last reason you should have your 3D printer repaired is that it can improve your printing experience. When you have a 3D printer that has been broken and malfunctioning for a long time, it may be difficult and irritating to use at times. Repairing your 3D printer ensures that it works properly no matter what you’re using it to print, allowing you to enjoy using this innovative technology in your home office, business or workshop.

In conclusion, there are a number of good reasons to have your 3D printer repaired. If your 3D printer has stopped working, then the best option is to get it repaired as soon as possible because this lets you save money in the long term, ensures that your 3D printer works like new again, and extends its lifetime. Contact the 3D Printing Store located in Denver, CO, and Dallas, TX, for repair services today!

3D printing service bureaus are a new and innovative way to get 3D printed parts and objects. 3D printers are becoming more affordable, but they can be tricky to use for those without experience or expertise in the field. This is where the 3D Printing Store comes in! From designing and scanning to creating prototypes and models, we can do it all quickly and efficiently, without the huge expense. We will discuss four reasons why you should consider using a 3D printing service bureau, such as ourselves. Contact us today to learn more!

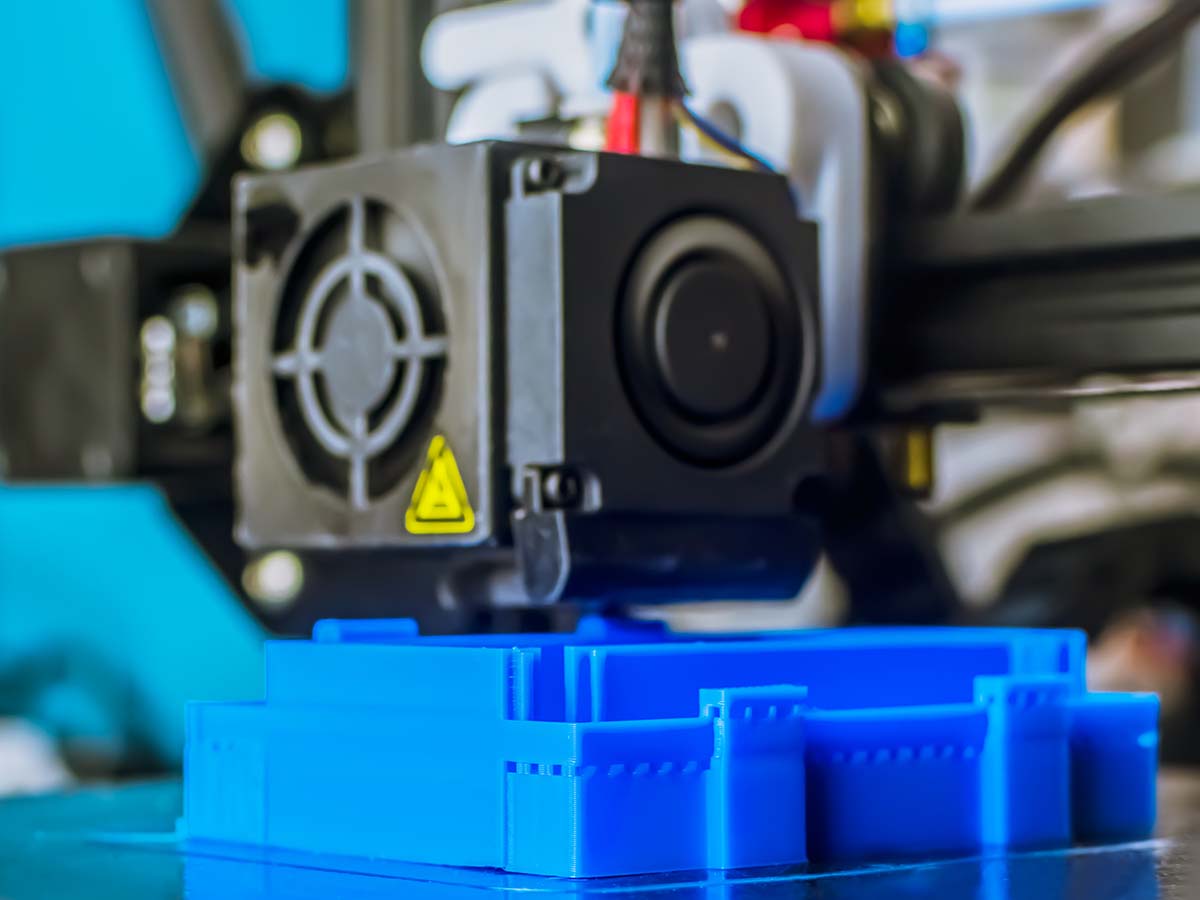

Advanced Equipment and Materials

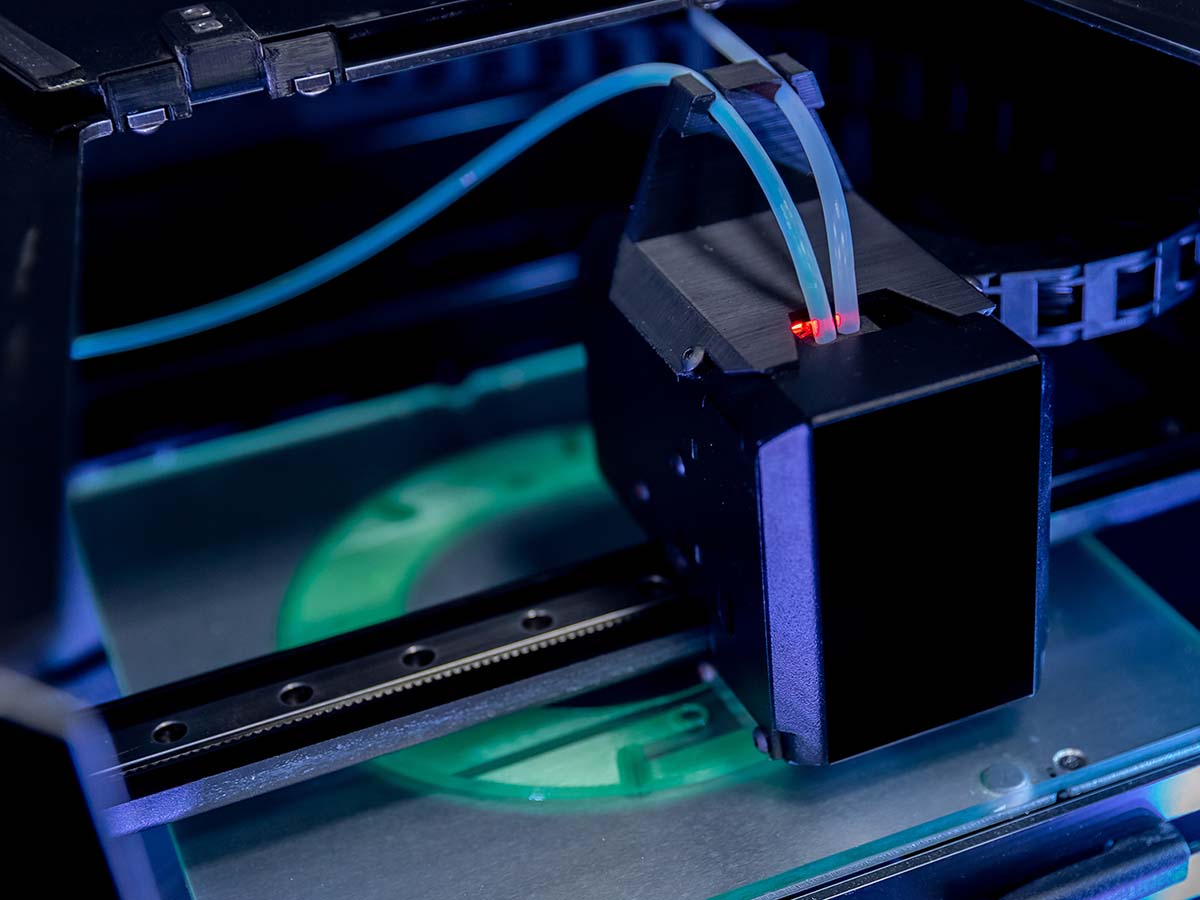

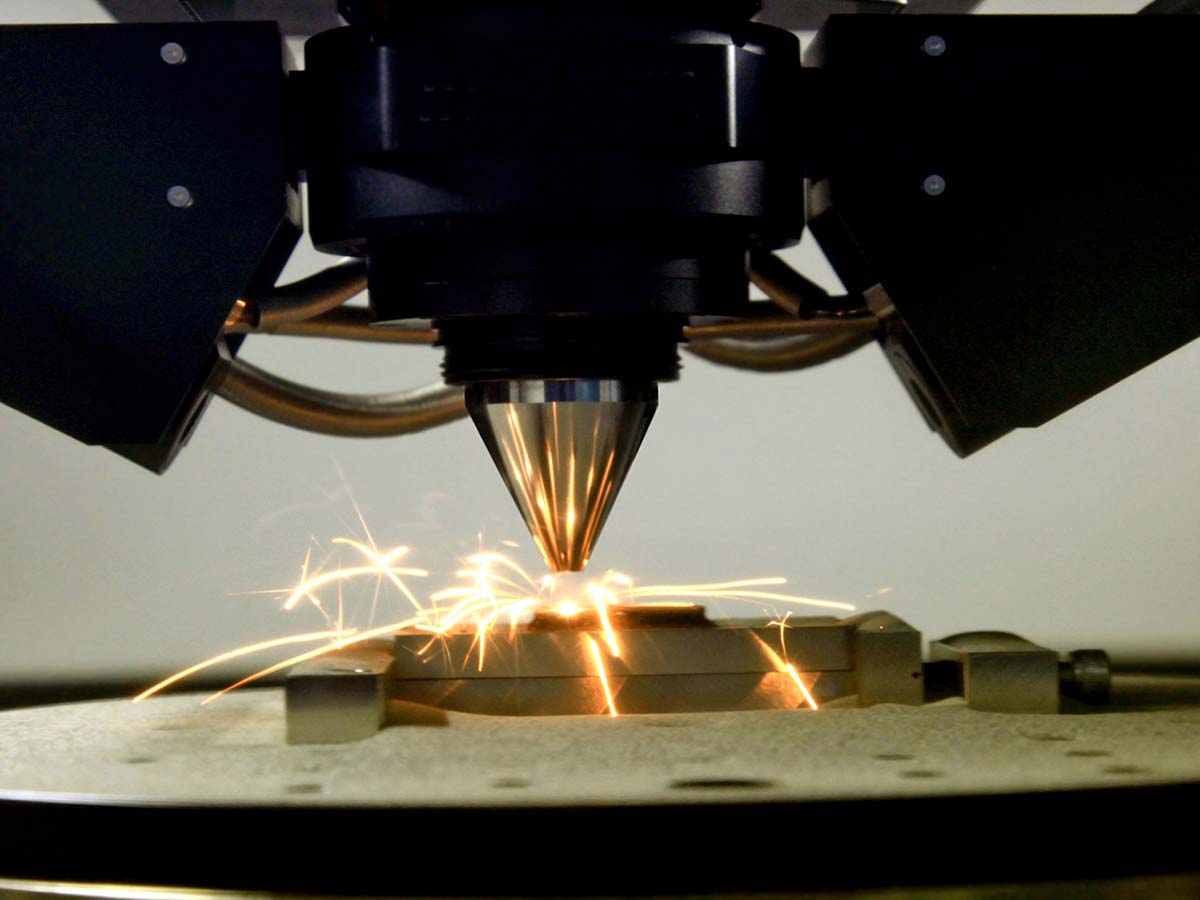

Our service bureau has invested in the latest and greatest technology to ensure that your prints are of the highest quality. We use advanced equipment like laser sintering printers, digital light processing and fused deposition modeling printers to produce parts quickly and accurately. In addition, we only use materials from leading suppliers to guarantee quality results.

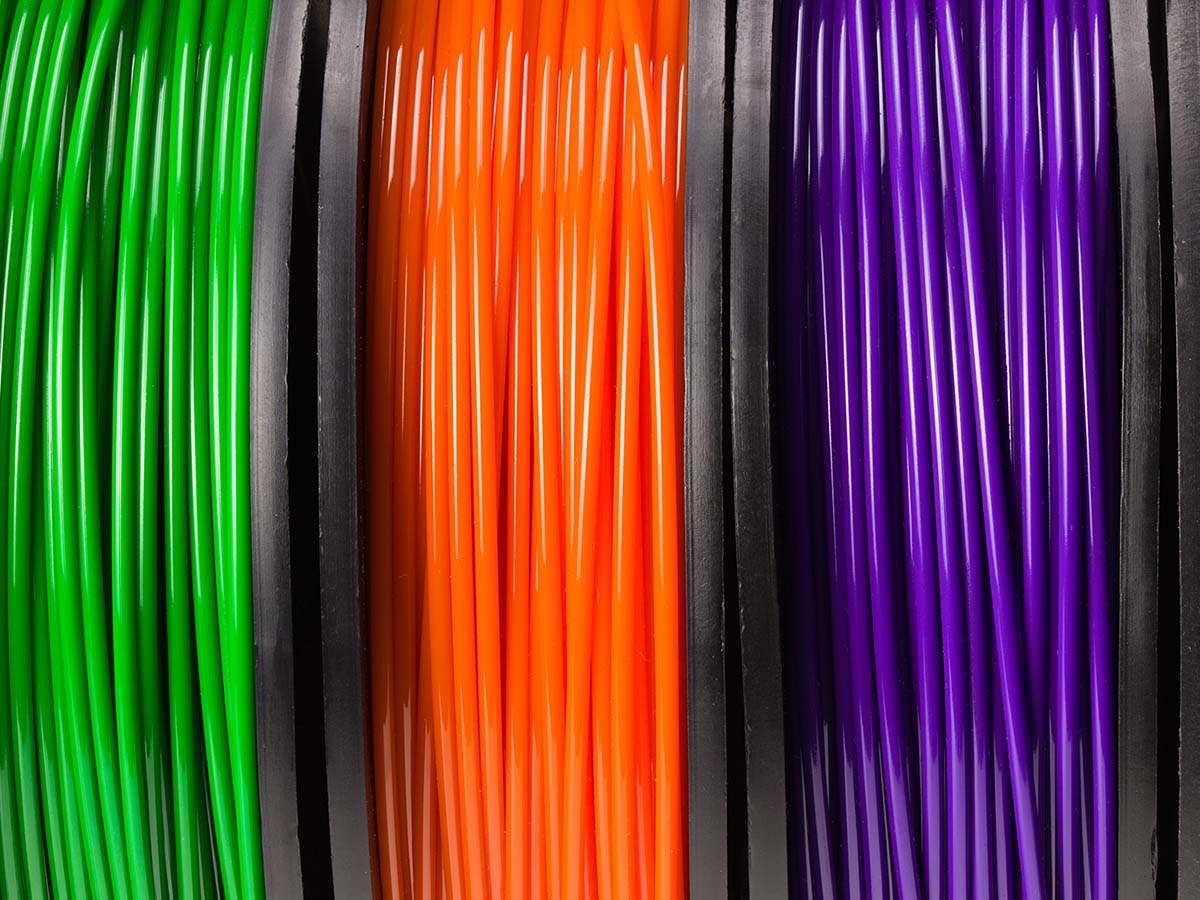

DIY 3D Printing Can Be a Big Financial Investment

When you factor in the cost of a quality 3D printer, replacement parts, upgrades, and filament, printing at home or for your business can quickly become an expensive endeavor. In many cases, using a service bureau is more cost effective than trying to print large volumes yourself. At the 3D Printing Store, we provide affordable and honest prices for all of our work. Get a quote today!

Equipped to Deal with Part Complexity or Volume

Most likely, you don’t have the right equipment to print in large volumes. Using a service bureau will allow for larger production runs without sacrificing quality or speed of delivery. We have many options available depending on your project requirements, so be sure to talk with one of our experts before deciding what would be the best fit for your needs.

Benefit from 3D Printing Expertise

At our service bureau, you can benefit from years of experience in the 3D printing industry. Our team has successfully worked on thousands of projects and will work closely with you to ensure that your project is completed according to your requirements, and will exceed your expectations.

The 3D Printing Store will save you more time and money compared to traditional manufacturing. With our experience and top-of-the-line technology, we will be able to handle any project you throw at us. If you’re looking to get a project printed, or you have some questions about our services, please don’t hesitate to contact the 3D Printing Store located in Denver, CO, and Dallas, TX! We would be happy to answer all of your questions.

Get 3D Printing Help From the 3D Printing Store in Colorado and Texas

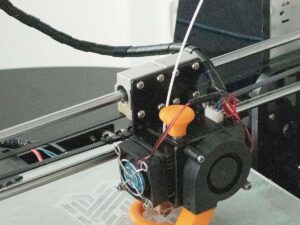

If you own a 3D printer, you know how expensive they can be. Therefore, it’s crucial to ensure that yours is running smoothly and efficiently. Here are four ways to keep your 3D printer running smoothly, longer. If you ever need 3D printer repair services or assistance, rely on the experts here at The 3D Printing Store — we have locations in Colorado and Texas for all of your 3D printer needs. Keep reading to learn more about taking care of your 3D printer and our 3D printer repair services near you.

Clean the Nozzle Regularly

In order to keep your 3D printer running, it needs to be cleaned properly. At regular intervals, or about every 5 to 10 hours of printing, be sure to clean the printing nozzle. Using the right equipment for your machine, such as a wire brush, gently remove any excess material every so often. Please locate your printer’s manual for specific cleaning instructions. Or, simply contact your local 3D printing shop for assistance.

Clean the Build Plate After Every Print Job

Every time a print job is finished, be sure to clean the build plate. The build plate of a 3D printer is simply the surface on which the print job is created. The build plate should be cleaned with water and vinegar, or just warm soapy water, using a soft sponge. This will clean any dust that may have accumulated during printing. Be sure not to use anything abrasive as it can damage your machine’s surface over time.

Keep the Extruder Head Clear From Clogs

Your 3D printer could be susceptible to clogging, especially if you don’t pay attention to the extruder head. A clogged extruder head can cause a range of errors in your print job, from curved prints to no print at all. Before printing again, be sure that the filament is free of any strands or particles by using a small brush or compressed air.

Check for Loose Cables on the Machine

From the time that you turn your 3D printer on, no cables should be moved or touched at the rear of the machine. If they are, it could risk damaging your machine. If you notice any loose cables or wires near the back of the machine that should not be moving when touched, contact a professional to correct this problem before using your printer again.

Contact Us for 3D Printer Repair Services

At the 3D Printing Store, we offer 3D printer repair services for a wide range of printers and brands. Contact us today to schedule an appointment for your printer’s repair services!

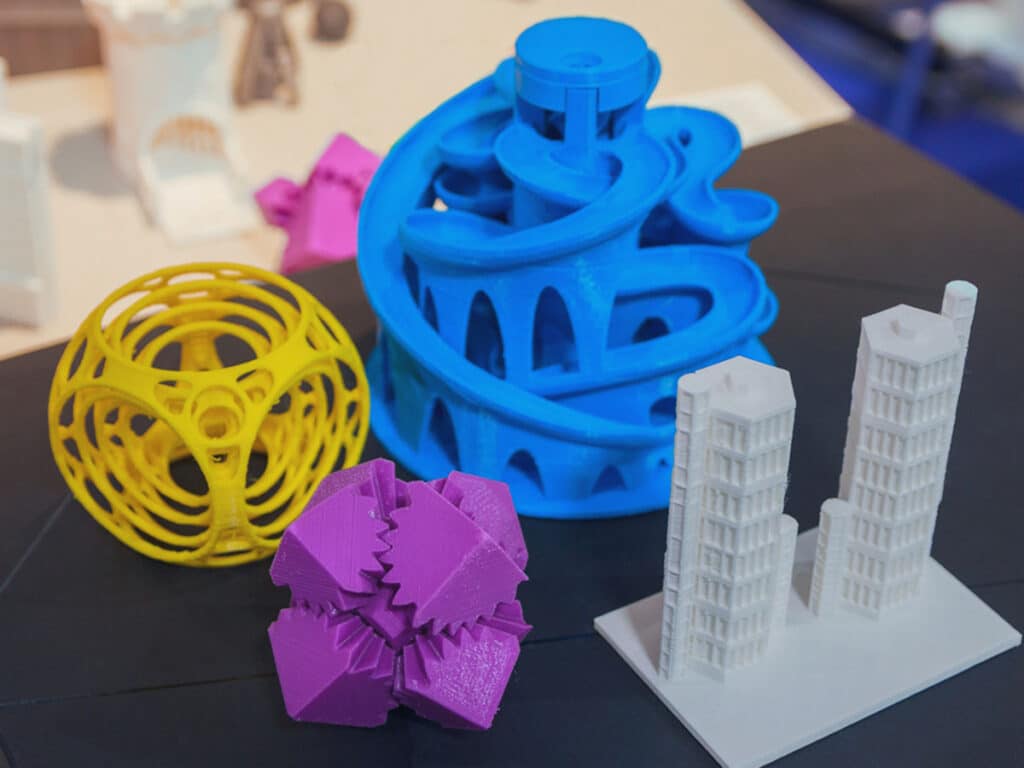

The spooky season is once again upon us, and it is time to figure out what costume you will wear. Picking a Halloween costume can be very stressful and, maybe, you may not have enough time to shop for one of the costumes available since they may be expensive or not your favorite. Well, have no worries, as 3D printers are here to solve your problems as you can print your costume. We got you covered at The 3D Printing Store in Colorado and Dallas, TX, as we offer various 3D services. Here are reasons why you should consider printing your own Halloween costume.

Saves on Money

Unlike the regular store-bought costumes, 3D printed costumes are likely to cost less as all you will need is a 3D printer and the printing materials. You can then design your costume or download a free template of the costume you want then print.

It’s Loads of Fun

Dressing up on Halloween is fun, but so is creating something from scratch and watching it get printed in real-time. Printing and putting together your own costume can be a very satisfying process, and you can even do it with your kids if you have any. Not only can you print complete costumes but also decorations such as pumpkins.

Endless Possibilities

Printing your own costume using a 3D printer gives you the freedom to get as creative as you want. You have the opportunity to create your own costume from scratch or download a design online and print it. Additionally, you have the freedom to completely express yourself as you can customize your Halloween costume however you deem fit.

Saves on Time

Depending on the Halloween costume you want, the printing process should be quick. Most costumes take a few hours, some twenty-four hours, and others can take even longer to print. Therefore, you should ensure that you start printing early, depending on your costume or props.

From making your own props and decorations to making your own costume, masks, and even armor, 3D printers have become useful. In addition, 3D printed costumes are often quite authentic, unique, and recyclable, making them waste-free. If you require any 3D printing services, feel free to check us out at The 3D Printing Store Colorado or look for any 3D printing store near you.

Need 3D printing services? Contact 3D Printing Store today!

Recently, the 3D Printing Store spent a day with the Colorado Advanced Manufacturing Association for the annual CAMA Golf Tournament. CAMA is an industry association proudly supporting Colorado manufacturers and dedicated to advancing the state manufacturing industry. For our 3D printing operation, it is an excellent opportunity to interact with different ideas and explore new trends!

Networking & Making Connections

While at the annual tournament, our 3D Printing Store connected with other members and learned more about a few new business opportunities. The event offered an overwhelming amount of support for new business directions as well as the future of our industry in Colorado. We are proud to have connected with industry members paving the way for advanced manufacturing in Colorado.

Learn More About the 3D Printing & Manufacturing Community

The 3D Printing Store is proud to have participated and supported this association! Attending the CAMA Golf Tournament proved to be extremely valuable in gaining fresh perspectives on the forward-thinking direction of the 3D printing industry.

If you would like to know more about our experience at the CAMA Golf Tournament, get in touch! Visit our website to find out about the value of additive manufacturing in the 3D industry today!

Held annually at the Broadmoor Hotel in Colorado Springs, the Space Foundation and many partners, including the 3D Printing Store, host The Space Symposium. This year marks the 36th symposium, designed to bring together companies, as well as the United States defense and government assets. Colorado continues to be a key player in the aerospace industry and touts its location as a #milecloser to space and the 3D Printing Store is pleased to participate and support this industry!

Networking

From the venue atmosphere to the agenda, The Space Symposium creates an exciting environment for networking, allowing customers and experts involved in revolutionizing space technologies to meet. Bringing participants together, this aerospace-center event provides an opportunity for growth and discussion. The 3D Printing Store is proud to be part of these networking opportunities and to help several large companies contribute to man’s exploration of space.

Influence

The Space Symposium represents all sectors of the space community, including commercial space businesses and subcontractors, military personnel, and national security organizations. Space entrepreneurs, space travel providers, and educational institutions engage in revolutionizing space technologies. The 3D Printing Store is fortunate enough to join these organizations and individuals, and is proud to have the opportunity to view and develop new space innovations. We believe 3D printing has its own place with regards to key space matters and technology.

Notability

The annual Space Symposium has long been a stage for many notable leaders in the space industry. This event holds a host of prominent national state officials, astronauts, and space travelers. Bringing the focus of critical space innovations to attention as well as providing a unique opportunity to examine this industry from multiple perspectives.

Explore 3D Printing Store & Our Influence

The impact of 3D printing in the aerospace industry is revolutionizing the speed and process of new parts and pieces in space technology. These innovations are an essential part of the space industry. Our team of experts is proud to attend the Space Foundation’s annual Space Symposium two-day conference in Colorado Springs, Colorado. We are proud to support and recognize this crucial forward-thinking industry that represents the latest in space technology innovations.

If you attended the 36th Space Symposium, what were your thoughts? What was your experience like? We’d love to compare our notes with you.

Meet with our experts at The 3D Printing Store to learn more about our additive manufacturing solutions for space technology as well as defense. Whether printing parts, providing filaments, or revolutionizing your project, we can do it all. Contact us today!

September 15th to October 15th is National Hispanic Heritage month. The 3D Printing Store has been actively involved with Mujeres de Colores in Fort Collins regarding the printing of replicas of the Hand that Feeds Monument that is going to be dedicated on October 9th at the Sugar Beet Park in Fort Collins, CO at 11:00 AM. To find out more about the Hispanic and Mexican individuals that worked the beet fields in Fort Collins in the early 1900’s you can also attend and view Betty Aragon-Mitotes film debut at the Lincoln Center on October 1st at 6:00 PM.